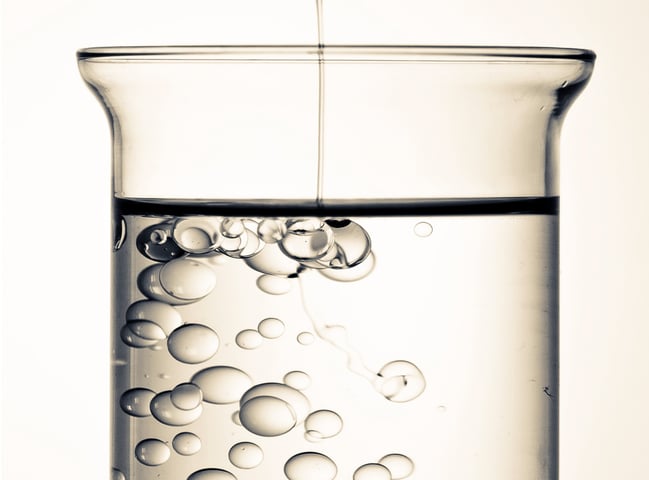

Force tensiometer can be used to measure interfacial tension. These instruments are based on measuring the forces exerted on a probe that is positioned at the liquid-liquid interface. The probe is connected to a very sensitive balance and the liquid interface of interest is brought into contact with the probe. The forces measured by the balance as the probe interacts at the liquid-liquid interface can be used to calculate the interfacial tension. The force depends on the following factors: size and shape of the probe, contact angle between the probe and the liquid, and the interfacial tension between the liquids. The size and shape of the probe are easily controlled. Probes are typically made of platinum which helps to ensure a zero degree contact angle between the probe and the liquid to be studied. Two configurations of probes are commonly used; du Noüy ring and Wilhelmy plate.

Interfacial tension measurement with Du Noüy ring and Wilhelmy plate

Interfacial tension measurement with the Du Noüy ring is based on the same principle as surface tension measurement.

However, in interfacial tension measurements, the ring is first immersed in the denser phase which is typically water. Then the less dense liquid, often oil, is poured on top. Care must be taken not to contaminate the ring when pouring the liquid. The measurement is then started and the sample stage with the liquid container is moved down. When the ring is at the interface, the software will detect that automatically and continue to move the stage down until the detected force starts to drop. This will indicate to the software that the maximum force is already passed, and the stage can move up again (i.e. ring moves down) and the measurement can be repeated.

The measurement should always be done from polar liquid to dispersive. Typically, this means the aforementioned situation where the ring is first immersed in water which is also the denser phase. In some rare situations, the water is a less dense liquid. This is, for example, the case when interfacial tension between water and fluorocarbons is being measured. Then the measurement needs to be started again with the ring in the water phase, but the stage will now start to move up as the water is the top phase. This method is called a push mode. There is a need to use an additional weight on the du Noüy ring for it to push through the interface.

For software to be able to calculate the interfacial tension, the densities of both phases are required as a correction needs to be done to measured results. This is done automatically by the software.

Wilhelmy plate can also be used to measure interfacial tension. The measurement principle is similar to Du Noüy ring but now a platinum plate is used as the measurement probe. However, when the Wilhelmy plate is used, the buoyancy caused by the light phase needs to be compensated. Due to slightly more complex measurement, the Du Noüy ring is more often used for interfacial tension measurements.

Interfacial tension measurement between two immiscible liquids is based on the

Interfacial tension measurement between two immiscible liquids is based on the