- Get precise control of the thin film thickness and packing density

- Create homogeneous depositions over large areas

- Add your coating to any solid substrate

- Build multilayer structures with varying layer composition

- Products

- KSV NIMA

- Fabrication & Deposition of Thin Films

- Nanoparticle Deposition

Thin Film Coating Solution

Nanoparticle Deposition

Combining the capabilities of Langmuir-Blodgett Medium Trough, MicroBAM and Langmuir-Schaefer Holders this readymade package is the ultimate tool for nanoparticle coating creation.

What you can do

A quick view

This 3-minute video is the fastest way to explore our thin film coating solution from KSV NIMA. Watch the video in fullscreen for the best experience!

3 reasons to invest

Outstanding versatility

See your film

Maximum value

Cover your needs

Study the table to find out what instrumentation you need for your research.

| Dip Coaters | Langmuir- Blodgett |

Thin Film Coating Solution Package | ISR, SPOT | |

| Simple coatings | X | X | X | |

| Advanced coatings | X | X | ||

| Advanced coatings with pre-disposition check | X | |||

| In-depth nanoparticle layer structure studies | X |

Would you like to get the full brochure to your inbox?

A closer look

The Nanoparticle Deposition package contains one Langmuir-Blodgett Medium Trough, the MicroBAM Brewster Angle Microscopy and Langmuir-Schaefer Holders. Below you can find the specifications for each of the items.

Langmuir-Blodgett Medium Trough

| LB Medium Trough |

|

Surface area (cm2) |

273 |

Trough top inner dimensions

|

364 x 75 x 4 |

Maximum compression ratio |

10.8 |

Barrier speed (mm/min) |

0.1...270 |

Balance measuring range (mN/m) |

0...300 |

Maximum balance load (g) |

1 |

Balance resolution (μN/m) |

0.1 |

Langmuir trough top |

• |

Total subphase volume (mL) |

109 |

Langmuir-Blodgett trough top |

• |

Total subphase volume (mL) |

176 |

Dipping well dimensions(L x W x H mm) |

20 x 56 x 60 |

Maximum sample size(T x W x H mm) |

3 x52 x56 (2 inches) |

Dipping speed (mm/min) |

0.1…108 |

Extraction angle |

- |

Upright microscopy troughtop |

- |

Inverted microscopy trough top |

• |

Ribbon barrier trough top |

• |

Compatible with |

|

KSV NIMA ISR |

- |

KSV NIMA MicroBAM |

• |

KSV NIMA SPOT |

• |

• : Available

– : Not available/Not applicable

MicroBAM

|

|

KSV NIMA MicroBAM |

Measurement |

|

Angle-of-incidence range (°) |

53, fixed |

Light source power (mW) |

50 |

Light source wavelength (nm) |

659 |

Image resolution (µm) |

12 (horizontal image direction, center)1 |

Field of view (µm) |

3600×4000 |

Polarizer |

Integrated (p-polarisation of the incident beam) |

Analyzer |

Integrated |

Camera |

|

Type |

USB |

Resolution (px) |

640×480 |

Framerate (fps) |

30 |

Adjustable exposure time and gain |

√ |

Image processing |

|

Image resizing |

√ |

Contrast enhancement |

Profile |

Image filtering |

√ |

Particle size determination |

√ |

Hardware |

|

Instrument dimensions (L×W×H, cm) |

22×27.7×40.2 |

Measuring head dimensions (L×W×H, cm) |

5.7×16.2×7.2 |

Power supply (V, Hz) |

100-240, 50/60 |

Weight (kg) |

10 |

Compatibility with L & LB Troughs |

|

Medium |

√ |

Large |

√ |

High Compression |

√ |

Alternate |

√ |

1According to Rayleigh’s criterion

2P-polarization of the incident beam

KSV NIMA LB Software

KSV NIMA LB Software is a powerful tool for creating coatings and studying Langmuir films. Based on 30 years of experience, KSV NIMA LB Software includes all the tools needed for effective and easy measurements and data processing.

The versatile measurement modes enable measurements from dipping all the way to compression isotherms, adsorption studies and interfacial rheology. The software saves the entire measurement setup together with the results for convenient analysis. All data can be easily viewed, plotted, reported and exported as needed.

Measurement features

- Coating mode, for depositing material layer, including a coating effectiveness parameter transfer ratio, keeping the packing density constant throughout dipping

- Compression/relaxation isotherms, for molecular interactions and phase changes

- Isochores/isobars, by automatically keeping the pressure stable and following temperature/area changes

- Monolayer kinetics, for enzyme, polymerization or any other zero-order reactions

- Adsorption and penetration of enzymes, proteins, peptides and similar molecules

- Interfacial rheology, for viscoelastic studies of Langmuir films, for emulsion or foam stability, with oscillating barriers method

- Integrated KSV NIMA characterization tool functions, for easy integration, such as automatic image recording based on surface pressure when combined to KSV NIMA MicroBAM

Add more possibilities

Have a look at a few selected extras that will extend the capabilities of your setup.

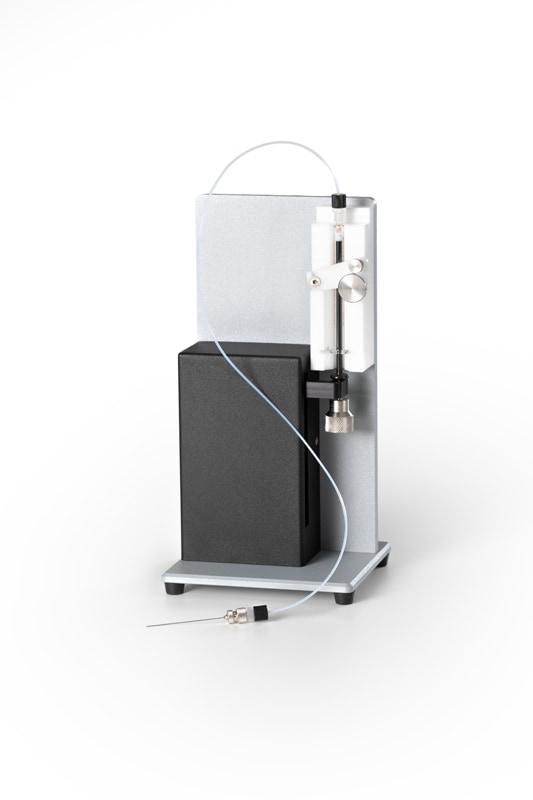

Syringe Pump

For PC-controlled monolayer sample introduction. Enables superior dispensing accuracy compared to sample introduction manually by hand. Controlled with the KSV NIMA LB software. Dispensing resolution 0.1

See how it works

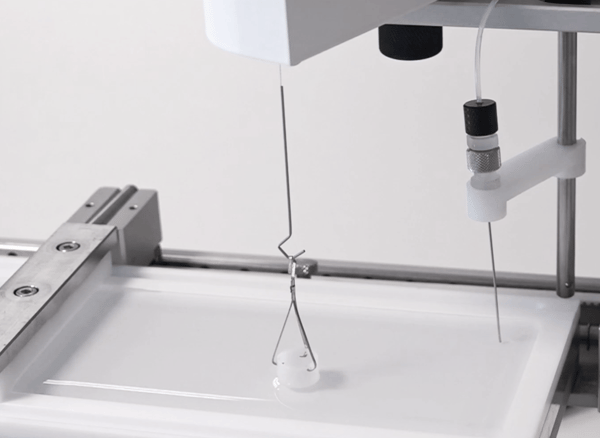

Subphase Evaporation Compensation Tool

SPOT

The KSV NIMA Surface Potential Sensor (SPOT) is used for determining molecular orientation changes in Langmuir films. Together with the surface pressure sensor included in all KSV NIMA Langmuir and Langmuir-Blodgett Troughs, it gives an in-depth view of the Langmuir monolayer interactions.

Learn more

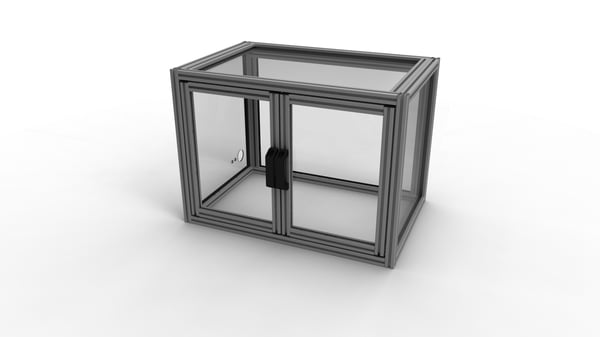

Cabinet CABI Small

In situations where an ideal cleanroom environment is not available, a suitable alternative may be to house your instruments in one of our dust and draught exclusion cabinets. KSV NIMA cabinets are made from an aluminium frame with clear acrylic glass panels on all sides including the doors at the front. There is no base to the cabinet, making it easier to house/un-house your instruments, should you so wish. The cabinets are equipped with connectors for water tubing and electric cables.

Learn more

We have gathered all our in-depth knowledge associated with Nanoparticle Deposition. Browse around amongst webinars, white papers and overviews to find a topic of interest.

- KSV NIMA

Highly Controlled Nanoparticle Deposition

- KSV NIMA

Creating Organized Nanomaterial Coatings with the Langmuir-Blodgett Method

- KSV NIMA

Solution Based Deposition of Graphene and Graphene Oxide

- KSV NIMA

A Practical Guide to the Deposition of Nanoparticle Monolayer

- KSV NIMA