Plasma treatment is a widely used way to prepare surfaces for coating, printing, and bonding by increasing their surface wettability. Combined with contact angle and surface free energy measurements, it lets you both optimize treatment conditions and verify surface quality over time.

Plasma treatment is widely used to prepare surfaces for coating, printing or gluing. By exposing a material to ionized gas, the process alters its surface chemistry in a way that increases surface energy and with it, wettability. This is especially valuable for polymers, which are used in many applications due to their mechanical properties but tend to have low surface free energy and poor initial wettability. With plasma treatment, these materials can be made more receptive to liquids and coatings in a controlled and environmentally friendly way.

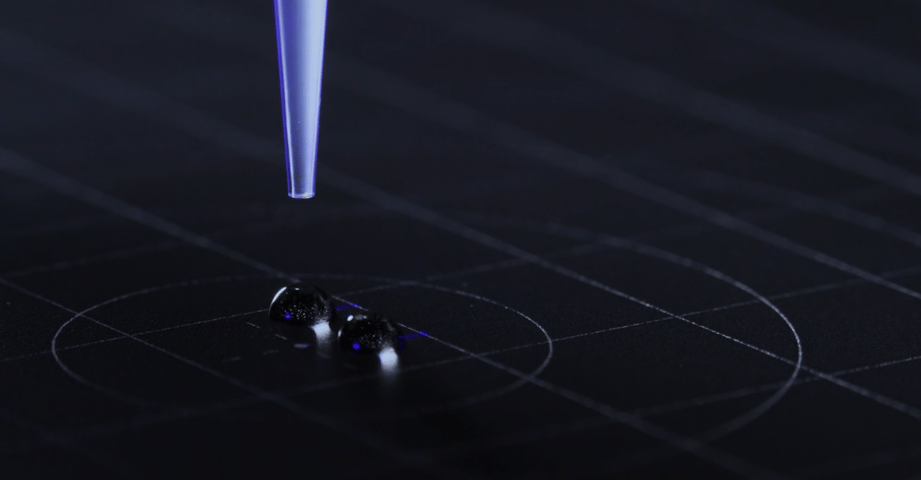

To evaluate effectiveness of the plasma treatment, contact angle measurements are typically used. The contact angle - the angle formed where a liquid droplet meets the solid surface - is very sensitive to small changes in surface chemistry. A decrease in water contact angle after treatment indicates improved wettability, while measurements with multiple liquids can be used to calculate surface free energy and its components. Together, these measurements provide a straightforward way to compare different plasma settings, identify optimal treatment conditions, and follow the stability of the treatment over time.

By measuring contact angles and surface free energy for different plasma gases, pressures, powers and treatment times, you can quickly see which combinations give you the desired wettability, instead of relying on trial and error.

By following contact angle over time after treatment, you can see how quickly the surface relaxes back toward hydrophobicity and set practical limits for how long you can wait before coating, printing or bonding.

Contact angle and surface free energy values give you clear, numerical evidence of surface treatment quality, making it easier to communicate with colleagues, customers and regulatory stakeholders.

Polypropylene (PP) is widely used in medical and technical applications, but its inherently hydrophobic surface leads to poor wettability for many liquids and coatings.

In this case example, PP samples were treated with air plasma for different durations and evaluated with contact angle measurements using three probe liquids. The study illustrates how contact angle and surface free energy measurements can be used to tune plasma parameters and define a robust process window for both development and quality control.

-1.webp?height=480&name=biolin-water-on-hydrophobic-fabric%20(1)-1.webp)

Our optical tensiometers offer several measurement possibilities to evaluate plasma-treated surfaces and polymers.

Attension Theta Lite is a robust optical tensiometer designed for straightforward, repeatable contact angle measurements. It is ideal for both detailed plasma treatment optimization in R&D and straightforward QC checks in production.

Its durable construction and long instrument lifetime make it a reliable choice for laboratories and production environments where consistent performance and low maintenance are important.

With ready‑made measurement recipes, robust analysis tools, and data handling suited for regulated environments, Theta Lite helps your team translate surface science into reliable, everyday practices.

Numerical contact angle and surface free energy values instead of subjective dyne pens or water break tests.

Easy to implement in the lab with default measurement recipes in place.

One platform for process optimization in the lab and routine checks in production.

Access to comprehensive learning resources such as tutorials, webinars and white papers.

Plasma treatment opens powerful possibilities for tailoring surfaces - when you can confidently verify its effect on each surface you treat.

By combining plasma processes with robust contact angle and surface free energy measurements, you can optimize your process parameters, control hydrophobic recovery, and secure quality in everyday production.

Download case study "Determination of optimal plasma treatment time of polypropylene"

Read our blog post on "Contact angle measurements to evaluate plasma treatment efficiency"

Read our blog post on "Plasma treatment and hydrophobic recovery of polymers"

Download our white paper on "Adhesion -how to use contact angle measurements to predict adhesion and bonding."