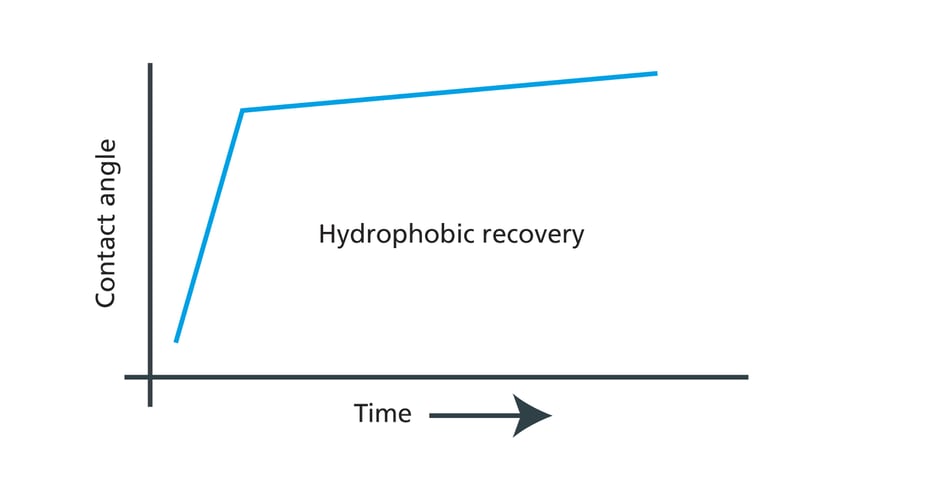

Most of the commonly used polymers are hydrophobic by nature. Hydrophobic surfaces suffer from poor wettability which makes addition of coatings on them challenging. Plasma treatment is one of the most widely utilized surface treatment methods to improve the hydrophilicity of the surfaces. Oxygen and nitrogen plasmas are most commonly used. Plasma treatment is able to increase the wettability of most polymers. However, hydrophobic recovery is often encountered which causes wettability to decrease as a function of time.

In a plasma treatment process, the surface is placed in a chamber under vacuum and bombarded by ionized gas. The ionized gas will induce chemical reactions at the surface of the material being treated, changing its surface energy. Typically, polymer surfaces exposed to oxygen or nitrogen plasmas become more hydrophilic due to formation of high energy surface groups in reactions between the native surface groups of the polymer and the reactive plasma species. In addition to surface chemistry, plasma treatment also often affects the surface topography. This means that in some cases, the surface roughness needs to also be taken into account when wettability of the surface is evaluated.

One common problem with hydrophilization is that it is typically not stable, and either a partial or complete hydrophobic recovery is usually observed. Typically the hydrophobic recovery is a significant drawback for most applications as the bonding ability will decrease when wettability of the surface decreases. The main reasons for the recovery have been identified as being the reorientation of the surface layer, or the migration of the polymer chains from the bulk of the polymer to the surface or from the surface to the bulk.

Contact angle measurements are used to evaluate the efficiency of the plasma treatment as well as the hydrophobic recovery process. Contact angle measurements offer an simple and fast method to check the wettability of the surface. In addition to basic contact angle measurements it is also possible to do combined contact angle and roughness measurements to see the effect of roughness on the contact angle data.

To read more about how contact angle measurements are utilized to determine the plasma treatment time, please download the case study through the link below.

Jokinen, V., Suvanto, P. and Franssila, S., "Oxygen and nitrogen plasma hydrophilization and hydrophobic recovery of polymers", Biomicrofluidics 6 (2012) 016501.

Learn how to use contact angle measurements to evaluate surface cleanliness on different materials and link cleaning steps to reliable adhesion and coating quality.

Learn how wettability, surface free energy and surface roughness define paper and paperboard surface properties – and how to measure them for reliable print, coating and sealing performance.

Smart materials are materials that sense a change in their environment and respond in a useful, reversible way.

Discover how contact angle measurements help optimize plasma treatment for improved wettability and adhesion in industrial applications.

Discover why contact angle is essential for adhesion, coatings, and quality control. Learn how surface wettability impacts product performance.

Discover why PFAS-free coatings are needed, the challenges they present, and key strategies for developing high-performance alternatives.

At the heart of droplet formation are two key molecular forces: cohesion and adhesion.

Contact angle measurements provide a golden standard for evaluation of surface properties for quality control.

Contact angle is the angle a droplet forms in contact with a solid surface. Thermodynamically, it is a balance between cohesive and adhesive forces.