What do wood, ice, and the disks in a human spine have in common? They are all viscoelastic materials. Viscoelasticity is a quality involving both viscous and elastic properties at the same time. QCM-D is a surface-sensitive technology that can characterize the viscoelastic properties of thin molecular films as well as bulk materials.

There are many materials that exhibit viscoelastic properties, ranging from natural biological structures such as tissue, cartilage, and skin, to synthetic polymers and concrete. Being viscoelastic means that the material to some extent both behaves like a liquid and a solid material and that it has a time-dependent strain.

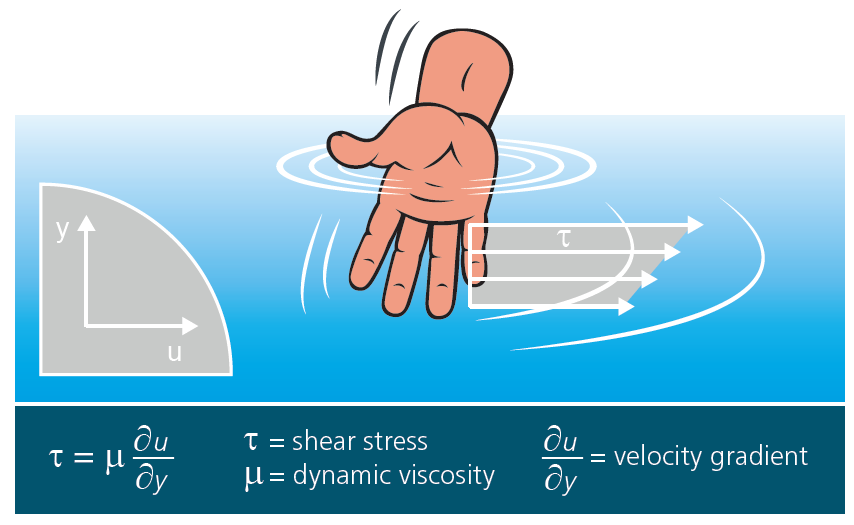

As illustrated in Fig. 1, viscosity describes a fluid's resistance to flow. The higher the viscosity, the larger the force needed to generate a specific flow. If you compare for example honey with milk, where honey has the highest viscosity of the two, honey has a viscosity of 10 Pa·s, which is about three thousand times that of milk which has a viscosity of 0.003 Pa·s. And this is why honey does not flow as easily as milk does.

Figure 1. The definition of dynamic viscosity: the proportionality between applied shear stress and the induced flow velocity gradient.

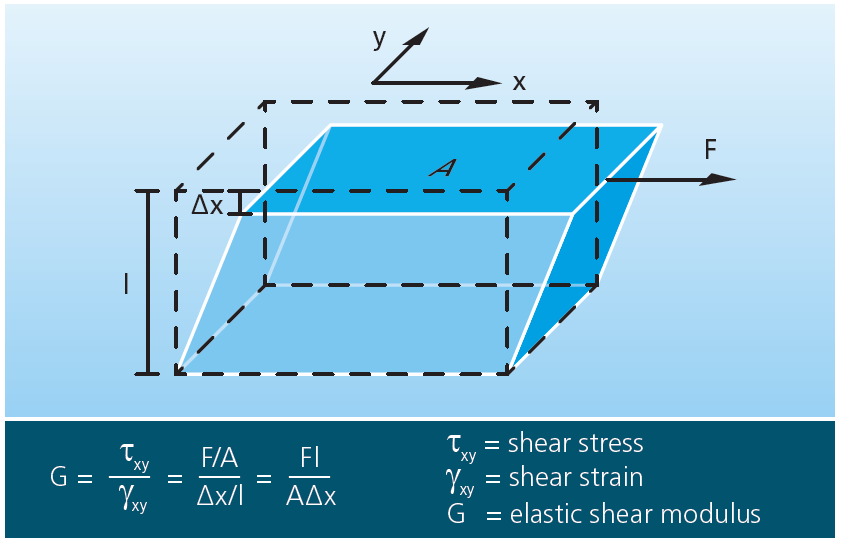

Elasticity is a material-characteristic property that describes a solid material’s resistance to deformation and is given in Pa, Fig. 2. The elasticity describes how a certain applied force will make a solid material deform, and the higher the elasticity, the more force will be required to cause a given deformation. For example, think of rubber compared to metal (elastic to some degree), where the metal has the highest elasticity.

Figure 2. The definition of elastic shear modulus: the proportionality between applied force and the induced shear deformation.

There are different elastic moduli, describing slightly different stress situations:

Hard solids, such as diamonds, have very high elastic moduli (shear modulus of 478 GPa), meaning that a large stress is required to deform the material. Softer solids, such as aluminum, on the other hand, have lower elastic moduli (shear modulus of 25 GPa), since less stress is required to induce deformation.

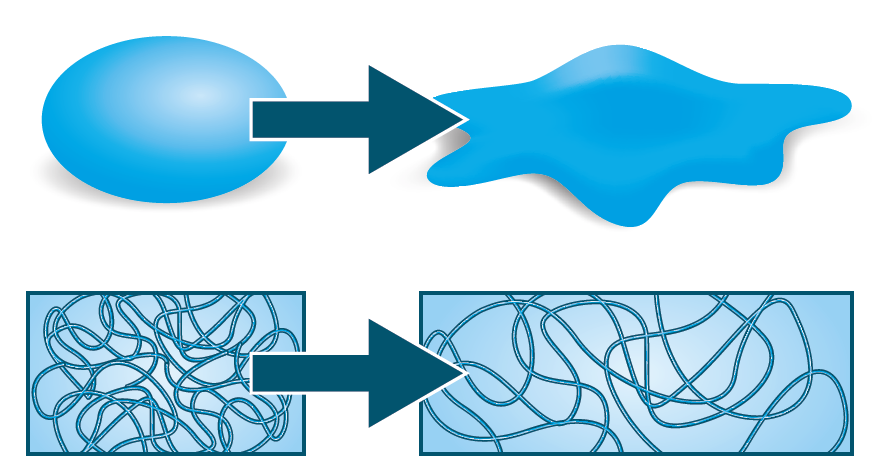

Viscoelastic materials can behave predominantly as viscous or predominantly as elastic, or equal, depending on the magnitude and the time scale of the applied shear stress. For example, toothpaste behaves as a viscous material when squeezed out from the tube, but is mostly elastic when at rest on the toothbrush for it not to run off. The same holds true for paint. If stress is applied with the paintbrush, the paint spreads on, e.g., the wall, but when it is left to rest it is preferred that it stays on the wall without running down onto the ground. Another example is play dough or "silly putty" that when rolled between your palms and tossed to the ground will bounce and act mostly elastic. When instead it is left to rest at a table it will eventually start to flow in a viscous manner. The explanation for this kind of viscoelastic behavior can be traced down to the molecular level, and the entanglement of the polymers constituting the paint, toothpaste, or play dough, Fig. 3. High entanglement results in a predominantly elastic behavior (toothpaste at rest or play dough under stress), while disentanglement gives a more viscous character to the material (paint under stress or play dough at rest).

Figure 3. The viscoelastic behavior of a polymeric material can be explained by entanglement and disentanglement processes on a molecular level. The latter results in a predominantly viscous behavior.

This is why it is highly interesting to be able to design and characterize soft matter materials at a molecular level. It can be done with a surface-sensitive technique such as QCM-D. By monitoring f and D at multiple overtones, not only the mass and thickness of the surface adhering molecular layer can be extracted, but also the viscoelastic properties (elastic shear modulus and viscosity). This could either be done for thin films attached to the sensor surface or for material in bulk, which is of use in the broad field of rheology and phase transition applications, for example. By monitoring the changes in the viscoelasticity of molecular layers attached to the surface, processes such as crosslinking, swelling, and other conformational changes can be followed in real-time and with high sensitivity.

If you would like to save this text for later, please download the pdf below.

Editor’s note: This post was originally published in March 2018 and has been updated.

Learn how QSense QCM-D reveals protein–surface interactions and adds interface-focused insight to biopharmaceutical formulation and stability work

Learn how QSense sensors enable application‑relevant biointerface interaction analysis and explore our sensor offering for different areas

Learn how QSense QCM D can be used to analyze swelling of thin films, including magnitude and dynamics.

Read about how molecule-surface interaction processes such as adsorption and desorption can be analyzed with QCM-D.

Learn best practices and step-by-step methods for accurate QCM-D coating thickness measurement on QSense sensors using QSense Omni.

Compared to QCM, QCM-D measures an additional parameter, and provides more information about the system under study.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Discover how QSense QCM-D helps tackle fouling challenges across industries

Discover how QCM-D enables real-time, label-free analysis of supported lipid membrane formation, structure, and dynamics for advanced research

Gabriel Ohlsson, Ph.D., is a former employee at Biolin Scientific where he initially held a position as an application scientist and later as a sales manager. Dr. Ohlsson did his Ph.D. in engineering physics and has spent a lot of time developing sensing technologies for soft matter material applications. One of his main tools during this research has been the QCM-D technology.