Why would you want to measure mass and thickness of thin films? One reason to monitor these two parameters is to characterize the build-up and degradation of molecular layers. Also, numerous materials and thin coatings are dynamic in nature and undergo physical changes responding to various stimuli, such as light, temperature, salt concentration or pH. These changes influence the mass, thickness and the structural properties of the material. The mass and thickness are therefore two parameters that are very much involved both the creation, behavior, and degradation of thin films. This makes them relevant to monitor both in the design, characterization, evaluation and optimization of thin films and coatings.

During surface interaction processes such as for example binding of molecules, adsorption, desorption, aggregation, and build-up of multilayer films, the mass and thickness of the molecular layers change. By measuring these changes in real time, we can follow the molecular binding processes and rearrangements. To measure these changes on a molecular scale, we need real-time nanoscale techniques. Once such technique is Quartz Crystal Microbalance with Dissipation monitoring technology (QCM-D). The QCM-D measures the changes of two parameters, the resonance frequency (f) and the energy dissipation (D). From these two parameters, mass and thickness changes at the surface can be extracted. In general, as the mass increases at the surface, the f will decrease. The D-parameter will indicate how soft the layer is. The softer the layer the higher the D. In the case of mass loss, the frequency will instead increase. And if the layer goes from soft to stiff, then the D parameter will decrease.

Molecules that are typically studied with this surface sensitive technology include lipids, proteins, DNA, polymers, surfactants, nanoparticles.

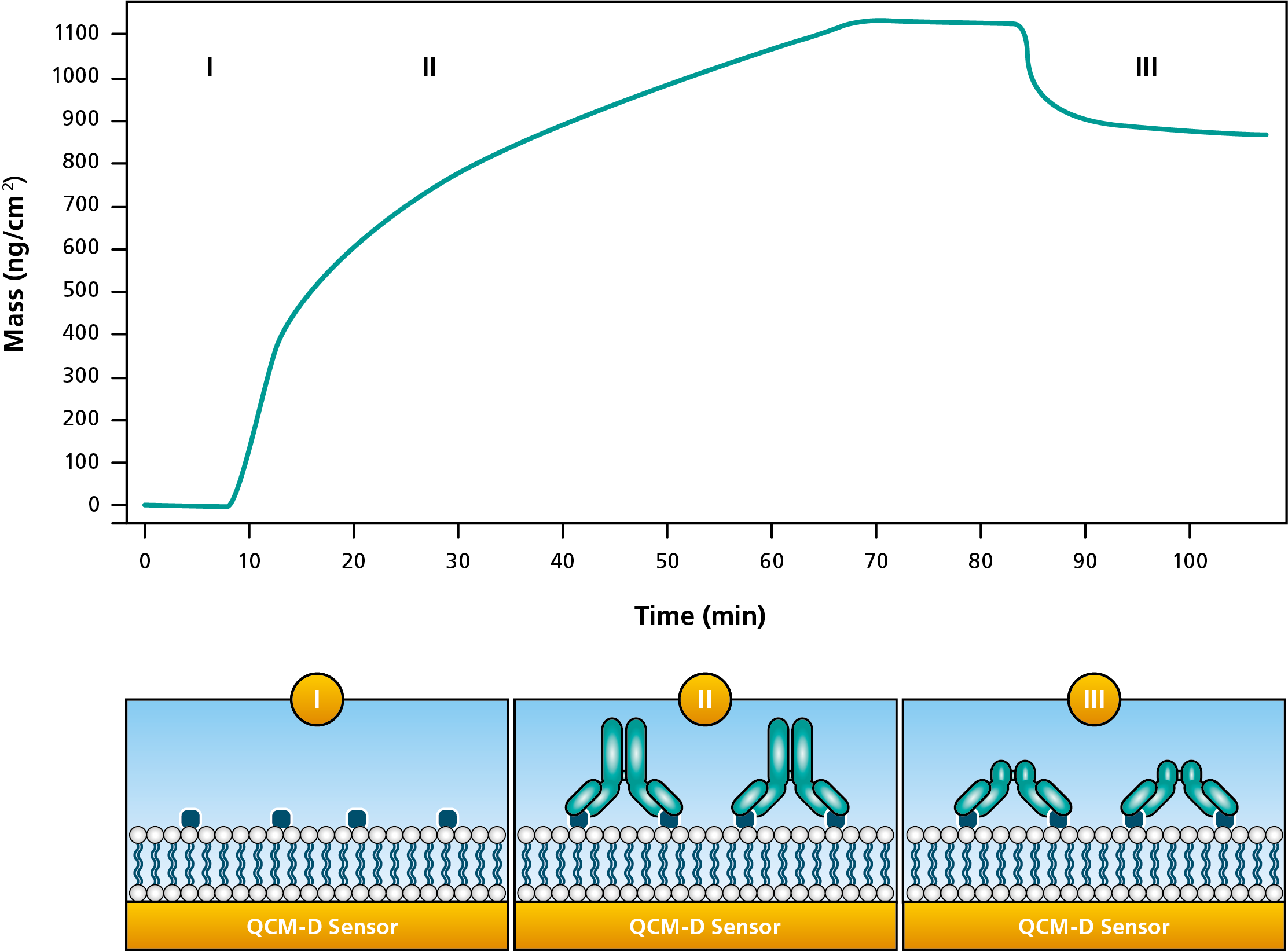

Let us take an example of a mass measurement. Here we are interested in detecting when an anti-biotin antibody first binds to a biotinylated lipid bilayer. We would also like to detect the cleavage of the antibody by an enzyme.

This measurement shows how monitoring of the mass changes allows us to detect both the binding of the antibody and the cleavage by the enzyme. Overall, the measurement offers insight in to both the molecular interaction processes and verifies the function of the enzyme as well as the direction of the antibody at the surface.

Figure 1. Mass changes as an antibody binds to the biotinylated bilayer on the surface (I-II) followed by enzyme cleavage (III) which removes 1/3 of the mass at the surface.

Download our overview to read more about what information you can extract from QCM-D analysis.

Learn how QSense QCM-D reveals protein–surface interactions and adds interface-focused insight to biopharmaceutical formulation and stability work

Learn how QSense sensors enable application‑relevant biointerface interaction analysis and explore our sensor offering for different areas

Learn how QSense QCM D can be used to analyze swelling of thin films, including magnitude and dynamics.

Read about how molecule-surface interaction processes such as adsorption and desorption can be analyzed with QCM-D.

Learn best practices and step-by-step methods for accurate QCM-D coating thickness measurement on QSense sensors using QSense Omni.

Compared to QCM, QCM-D measures an additional parameter, and provides more information about the system under study.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Discover how QSense QCM-D helps tackle fouling challenges across industries

Discover how QCM-D enables real-time, label-free analysis of supported lipid membrane formation, structure, and dynamics for advanced research

Learn how QSense QCM-D analysis can reveal membrane fouling dynamics and optimize cleaning strategies for more efficient water treatment

Learn how QSense QCM-D helps detect and prevent surface-induced instabilities in biologics. Join our webinar for insights and practical examples.

Gabriel Ohlsson, Ph.D., is a former employee at Biolin Scientific where he initially held a position as an application scientist and later as a sales manager. Dr. Ohlsson did his Ph.D. in engineering physics and has spent a lot of time developing sensing technologies for soft matter material applications. One of his main tools during this research has been the QCM-D technology.