Surface and interfacial tension play a key role in several industrial processes including, for example, detergents, coatings, and oil recovery to name a few. Surface tension measurements are carried out when new coating formulations are developed, or when the quality of a detergent is being evaluated. There are three main methods used to measure equilibrium surface and interfacial tensions. Two of the methods are based on force tensiometer; Du Noüy ring and, Wilhelmy plate, while the third is an optical method; pendant drop.

The Du Noüy ring method utilizes a platinum ring as the probe. The platinum ring is placed on a measurement hook connected to a highly sensitive balance. The ring is submerged below the interface by moving the platform on which the liquid container is placed. After immersion, the height of the platform is decreased, and the ring pulls through the interface bringing a meniscus of liquid with it. If the container is lowered further, the meniscus will tear from the ring. Prior to this event, the volume (and thus the force exerted) of the meniscus passes through the maximum value and begins to drop before the actual tearing event. The calculation of the surface or interfacial tension is based on the measurement of the maximum force and the perimeter of the ring.

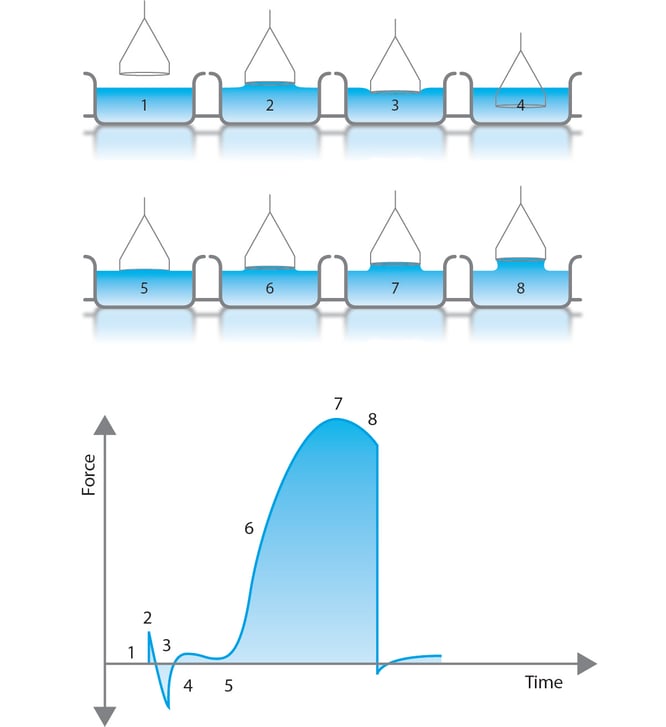

Figure 1. From force vs. time curves different stages of the experiment can be identified: 1) At the beginning, the ring is above the interface and the force is zeroed. 2) The ring touches the interface and there is a slight positive force due to the adhesive force between the ring and the surface. 3) The ring must be pushed through the interface (due to the surface tension which will cause a small negative force). 4) The ring breaks through the interface and a small positive force is measured due to the supporting wires of the ring. 5) When lifted through the interface the measured force starts to increase. 6) The force keeps increasing. 7) The maximum force is reached. 8) After the maximum there is a small decrease of the force until the lamella breaks, or the ring is pushed back below the surface.

Du Noüy ring measurement is done with the force tensiometer by placing the measurement cup on the stage and the probe on the hook as shown in the video below.

The Wilhelmy plate method utilizes a rough platinum plate as the probe. The calculations in this technique are based on the perimeter of the fully wetted plate in contact with the liquid. In this method, the position of the probe relative to the surface is significant. As the liquid surface is brought into contact with the probe, the instrument will detect the exact moment of contact by registering a change in force on the probe. This position is labeled the “zero depth of immersion”. The plate is then immersed to a set depth below this value (typically a few mm into the interface). When the plate is later returned to the zero depth of immersion, the force is recorded.

Similarly, it is possible to carry out the measurement by replacing the Wilhelmy plate with a platinum rod. The measurement principle stays the same, but the small diameter of the probe makes it possible to also measure smaller sample volumes. However, at the same time, the accuracy of the measurement is not as high as with the standard Wilhelmy plate technique.

As Wilhelmy plate or rod measurement is done with the force tensiometer, the measurement procedure is very similar to the one shown for the Du Noüy ring. Now, instead of the ring, a plate or the rod is hung on the hook. The measurement is run automatically after the start button is pressed.

Surface and interfacial tension measurements can be also performed optically using pendant drop shape analysis. The shape of the drop hanging from a needle is determined by the balance of forces which includes the surface tension of the liquid being investigated.

Modern computational methods using iterative approximations allow for solutions of the Young-Laplace equation to be found. Thus, the surface or interfacial tension between any two immiscible fluids with known densities can be determined. For optical tensiometry the size of the droplet is important, and it should have a tear or pendant shape.

If you are considering which method is best suited for your application, please download the white paper “Surface and interfacial tension – How to select the best measurement method”

This blog post was originally published on the 6th of February, 2018, and has been updated with videos and minor corrections.

A wetting agent is a surface-active molecule used to reduce the surface tension of water.

The term surfactant comes from the word surface active agent. At the interface, they align themselves so that the hydrophobic part is in the air and the hydrophilic part is in water. This will cause a decrease in surface or interfacial tensions.

Surface tension plays an important role in Li-ion battery slurry optimization.

Surface tension plays an important role in the electroplating solution.

When measuring contact angles or making surface tension measurements with a pendant drop, selecting the correct tip or needle for your liquid is crucial.

The surface tension of water is about 72 mN/m at room temperature which is one of the highest surface tension for liquid.

Surface tension is a quantitative measure that can be correlated with a solution’s ability to remove dirt.

Surface tension and wettability are important physical properties that play a significant role in the effectiveness of agrochemicals.