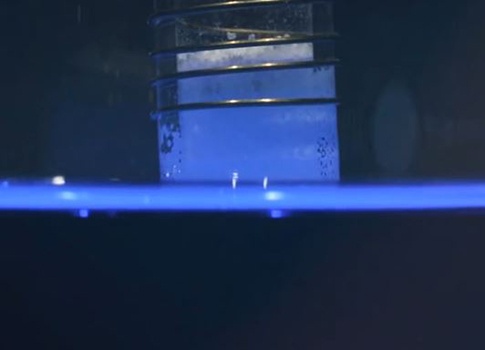

The wettability of loose powders and pigments is often evaluated by the sorption measurement of the liquid. A force tensiometer is utilized to detect the liquid penetration into the powder.

The power is packed on the powder holder which can be made of either glass or stainless steel. The holder is hanged on a very sensitive balance and then slightly immersed into the liquid. As the holder touches the surface of the liquid, the balance is zeroed after which the penetration of the liquid into the powder is recorded. Comparison of the speed at which the liquid is adsorbed gives some insight into the wetting properties of the powder but more common is the use of the Washburn equation to calculate the contact angle.

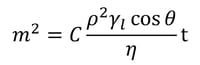

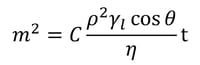

Washburn equation is written as

, where w is the measured mass, C is material constant, ρ is the density of the liquid, γl is the surface tension of the liquid, η viscosity of the liquid, t measured time, and θ contact angle.

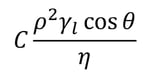

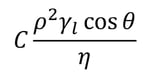

An experiment is performed where the mass of the adsorbed liquid is measured against time. The graph should give a straight line which slope is:

If viscosity, density, and surface tension of the liquid are known then there are two unknowns left in this term, contact angle and C, the material constant for the solid. To resolve the equation, one must perform a measurement with the completely wetting liquid. If the liquid completely wets the solid, the contact angle can be assumed to be zero. N-alkanes C6 – C10 are most typically used. Liquids like methanol, ethanol, or pentane, although most probably would wet the solid completely, might be too volatile. Thus, liquids like hexane, heptane, and octane are often used. To determine the most suitable complete wetting liquid for your powder, it is recommended that you run a series of tests to find the most wettable one.

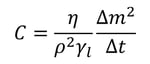

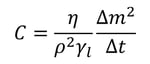

The material constant C can then be calculated

It is advisable to run the test at least five times to make sure you are able to get reproducible values for the material constant C. If the values vary a lot, this means that the packing of the powder into the holder is inconsistent. To get the packing of the powder consistent is mandatory as the material constant C depends on the packing density and distribution. If the material constant varies from measurement to measurement, the contact angle value for the powder cannot be reliably determined.

Once the material contact C is determined, the same packing method needs to be used to pack the powder for the actual contact angle measurements.

Most often the contact angle measurement is done against water. Here, an important note is that if the powder is hydrophobic, i.e. the contact angle with water is higher than 90 degrees, the method described cannot be used. This is since the liquid penetration happens through capillary action which is not possible with the contact angles above 90 degrees.

Another sometimes used method for powder wettability is the Wilhelmy plate. To use the Wilhelmy plate method, the powder needs to be either compressed into a thin disc or added as a coating on a glass slide with known dimensions. After the sample preparation step, the method is pretty straightforward as the measurement is done automatically by the software. One difficulty in the measurement is the determination of the true perimeter of the sample. An accurate perimeter is needed to calculate the contact angle. Due to this and somewhat difficult sample preparation, this method is not as common as the Washburn method or the sessile drop method discussed next.