In the packaging industry, adhesion and wettability play a key role in many processes. Packaging material typically includes various layers of different materials to fulfill all the requirements to protect and promote the product inside the package.

As a packaging material, paper is often used due to its relatively low cost and renewability. The barrier properties of the paper are not usually sufficient and thus different polymer coatings are applied to produce laminates. To ensure good mechanical properties for the laminates, adhesion between the polymer and paper must be optimized. Wettability and surface roughness play a key role in adhesion and can be studied with combined contact angle and surface roughness measurements.

Wood-fibers are typically modified either mechanically or chemically before final use in paper products. Novel fiber modifications, such as utilizing nanotechnology for fiber functionalization, are also topics of interest in research. Single fiber properties can be studied by force tensiometer or by using optical tensiometer combined with picoliter dispensing.

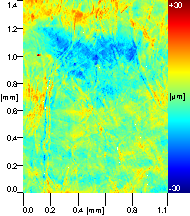

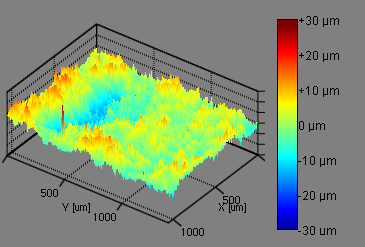

Due to their fiber-like structure, paper and board surfaces are almost always rough. This roughness influences wettability as it amplifies the wetting effect of the surface chemistry. In addition, different kinds of plasma and flame treatments used to improve printing quality affect both surface chemistry and surface roughness. It is thus important to evaluate the effect of roughness on contact angle.

An example below shows the effect of roughness on the contact angle. Both roughness and water contact angles were measured at three different sample locations. The measured contact angles show large variation in the contact angle readings especially in the case of hydrophilic base paper. When the effect of roughness is taken out by calculating roughness-corrected contact angles, the contact angles are much closer to each other. The difference in roughness-corrected contact is due to the surface chemistry of the surface. Combined contact angle and surface roughness measurements make it possible to evaluate how the degree of roughness affects the contact angle.

| Hydrophilic base paper | Hydrophobic base paper | |||||

| 1 | 2 | 3 | 1 | 2 | 3 | |

| Contact Angle ° | 57,6 | 63,6 | 72,3 | 128,0 | 128,2 | 125,3 |

| Contact Angle (corrected)° | 72,5 | 74,6 | 77,8 | 113,2 | 112,6 | 113,1 |

|

|

|

Another aspect of packaging is its visual appearance. Printing on the package is intended to promote the product inside. Quality of printing is affected by wettability, absorption and spreading of inks into porous paper. Printing on low surface energy polymer coatings can be challenging. The influence of internal and surface sizing on paper absorption properties can also be evaluated by contact angle measurements with an optical tensiometer. A high speed camera enables the study of very fast absorption phenomena, if needed.

Inkjet printing technology is increasingly used in home and office printing, but it has also become common in industrial printing, the packaging industry and functional printing applications. Optical tensiometer combined with picolitre dispensing can be utilized to demonstrate inkjet printability, especially ink-paper interactions.

Absorption properties of coating and ink pigments can be studied using the powder wettability method of force tensiometers.

Contact angle measurements to evaluate plasma treatment on extrusion coated paper

When non-absorbing and low surface energy plastic surfaces are printed, adhesion between ink and substrate is challenging. It is well-known that the surface free energy of the substrate should be higher than that of the ink. To ensure good printing quality, the surface free energy of the coated substrate should be increased by using a surface treatment method, such as plasma and flame treatments prior to printing.

Application note: Surface treatment evaluation in packaging industry

Tensiometry in inkjet printing applications

Inkjet printing is a versatile technique used in a wide range of applications, from small-scale home and office printing to high speed industrial printing and more novel functional printing applications. Since the interactions between the ink and substrate are crucial in defining inkjet print quality, tensiometry is widely utilized in this field.

Adhesion between the ink and substrate can be estimated by comparing the surface tension of the ink to the surface energy of the substrate. Absorption and spreading of droplet are studied by contact angle measurements. The picoliter dispenser option for the Theta optical tensiometer allows the same size range droplet formation as in the real-life inkjet process by using piezo-driven technology.

Application note: Tensiometry in inkjet printing

Learn about the effect of surface roughness and wettability on biocompatibility of biomaterials and medical devices.

This blog post describes the importance of fiber diameter on the contact angle measurements of fibers with Wilhelmy method

Standard contact angle measurement considers the surface's chemical properties. The influence of surface roughness is added by utilizing the Wenzel equation.