A traditional coating is usually applied either to protect the material beneath or to improve its visual appearance. More and more research interest is being put on coatings that in addition, can serve some other function. These types of coatings are generally called functional coatings.

The list of different functional coatings is extensive but some of the most studied are antifouling, antimicrobial, conductive, self-cleaning, photo and thermochromic, self-healing and superhydrophobic coatings.

Depending on the function the coating needs to fulfill, different coating strategies are required. The simplest functional coatings, where only little control over the structure of the coating and layer thickness is required, can be fabricated by using dip coaters. For more advanced coatings, Langmuir-Blodgett and Langmuir-Schaefer techniques offer precise control of the thin film thickness and packing density. The Langmuir-Blodgett technique has been utilized in deposition of nanoparticles for smart windows as well as deposition of graphene for electronic applications. Deposition of nanoparticles and the build-up of functional nanocomposite structures can also be characterized by QSense® QCM-D

There are several tools available for visual, molecular and wettability characterization of the coatings.

Superhydrophobic coatings have gained considerable interest due to their possible use in applications such as self-cleaning windows or anti-icing surfaces. As per definition, superhydrophobicity is achieved when the static contact angle with water is over 150° and the contact angle hysteresis is low. Characterization of the superhydrophobic coatings is thus accomplished by measurements of both static and dynamic contact angles.

As we are becoming more and more concerned for the future of our planet, different ways of saving energy are receiving more research effort. Large portions of our energy consumption are spent either on heating or cooling buildings. There are different solutions to improve the insulation properties of our buildings and novel smart windows are at the center of attention. One interesting class of smart windows is produced from a thermochromic material that can change its color as the temperature changes. Windows coated with thermochromic thin film are thus able to control the amount of heat transfer thorough the glass. In cold weather, the heat is kept inside, and during hot periods, the windows prevent infrared radiation from the sun entering the building.

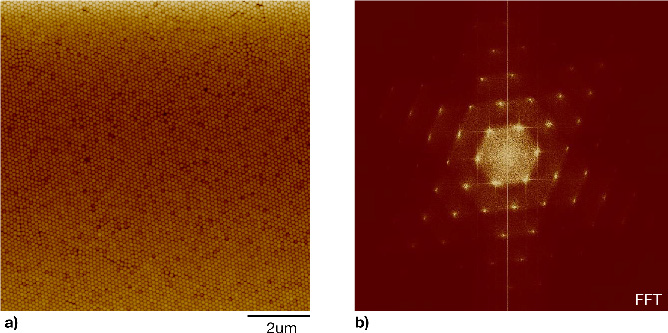

Researchers at University College London (UCL) have developed methods to coat glass surfaces with polystyrene nanospheres by using the Langmuir-Blodgett (LB) technique [1]. By utilizing LB they have produced highly organized nanoparticle layers that have been utilized as etching masks in a subsequent process. The produced nanostructures can be coated with vanadium dioxide and give the window the same anti-reflective properties found in the eyes of moths. It reduces the amount of light reflected internally in a room to less than 5%, which is significantly better than what has been achieved with other prototype vanadium dioxide coated windows [2].

A monolayer of 200 nm diameter polystyrene nanospheres deposited on a quartz substrate using the Langmuir-Blodgett technique on a KSV NIMA Medium trough. (a) AFM image of the monolayer, (b) a Fourier transform of the same image exhibiting the exceptional crystallinity achievable with this technique. Copyright Dr. Alaric Taylor.

In addition to improved reflectance properties of the windows, nanostructures also become self-cleaning. The window surface is ultra-resistant to water, meaning that when rain drops fall on the surface, they form spherical droplets that roll off the window easily, collecting dirt, dust and other contaminants and carrying them away. This is highly needed property, especially for windows used in skyscrapers where window cleaning is challenging. Self-cleaning properties of the surfaces are studied extensively by using both static and dynamic contact angle measurements.

[1] Taylor, A. Motheye smart windows Bio-inspired, temperature-responsive glazing for passive regulation of building temperature with the ability to self-clean (Unpublished doctoral thesis). (2016) University College London, London, UK.

[2] Taylor, A. et. al., A Bioinspired solution for spectrally selective thermochromic VO2 coated intelligent glazing, Optics Express 21 (2013) A752.

Blog post: Highly Organized Nanoparticle Thin Films

Single-sheet graphene (SG) is the first truly two-dimensional material and has been shown to have many outstanding material properties, such as high electrical and thermal conduction and high tensile strength. Many believe graphene is one of the most promising and versatile materials discovered to date. Potential applications for the material include building smaller and faster electronic circuits, developing stronger and more flexible construction materials, and creating more efficient electric batteries, to mention just a few examples. Graphene can act as both n- and p-type conductors and due to its semiconducting nature, this has raised speculation of it someday replacing silicon in electronics. Because of the electrical properties and transparency of SG layers combined with a good chemical resistance, one of the most interesting applications for graphene is for it to be used instead of indium tin oxide (ITO) or fluorine tin oxide (FTO) in optoelectonics, such as solar cells and light emitting diodes. [1-3]

There are several different ways of preparing SG. Among the most promising for large-scale industrial use are the different liquid phase exfoliation methods, which usually produce a dispersion of SG or single-sheet graphene oxide (SGO). The challenge is then in how to transfer the SG or SGO from the dispersion onto a support in a controlled manner. Langmuir– Blodgett and Langmuir-Schaefer (LS) deposition has recently shown promising results in preparing graphene layers with high degree of control.

Characterization of graphene oxide thin films can be performed directly on the Langmuir trough with Brewster angle microscopy. This enables the characterization of the thin film quality already prior the deposition step.

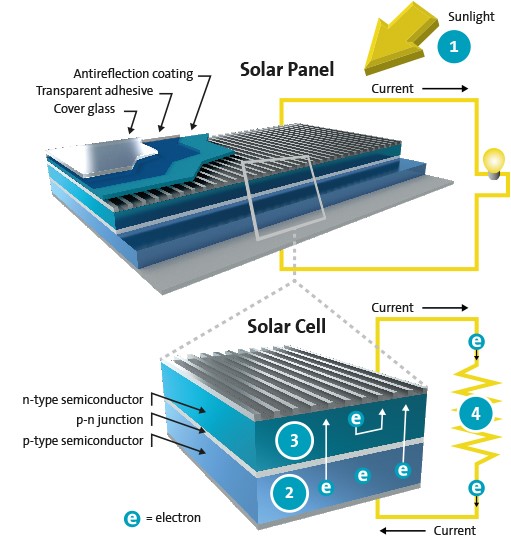

A solar cell (also called a photovoltaic cell) is an electrical device that converts the energy of light directly into electricity through photovoltaic effect (see Figure 1.). There are several types of solar cells available, the most common being fabricated on silicon wafer. Other solar cell types include thin film, dye-sensitized and organic/polymer solar cells. Although, silicon solar cells are by far the most commonly used with their over 80% market share, due to simple fabrication process, other solar cell types offer certain additional advantages such as flexibility.

There are currently many research groups active in the field of photovoltaics at universities and research institutes around the world. This research can be roughly divided into three areas:

Traditionally, the top layer of a solar cell is a thin cover glass, coated with a anti-reflection (AR) coating. Anti-reflective coatings are used to increase the absorption of photons and in this way, increase the efficiency of the solar cells. The sol-gel dip coating technology is a widely used method for producing AR layers on large areas.

During manufacturing, it is important to ensure a good adhesion between the different layers on the solar cell. Contact angle measurements are often utilized as good wettability indicates good adhesion.

Application overview: Fabricating highly organized nanoparticle thin films

Application note: Contact angle measurements in solar cell industry