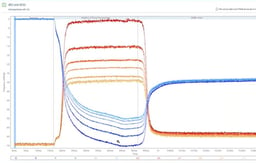

- A complete analysis toolbox

One software for all your needs - Intuitive interface

Dfind supports you all the way through your analysis process - from data preparation to final reporting - Guided modelling

To take you through your analysis step by step - Material library

Configuring your modelling setup is easy, just select your sample material from the list - Autoplotting

Visualizes your results throughout the whole analysis - Smart tools

Dfind offers several analysis methods including shifts, rates and slopes to help you extract the information you need - Analyze all data in one go

To save your time, Dfind allows you to review, model and analyze multiple data sets in one go

- Products

- QSense

- QCM-D Instruments

- QSense High Pressure

QCM-D

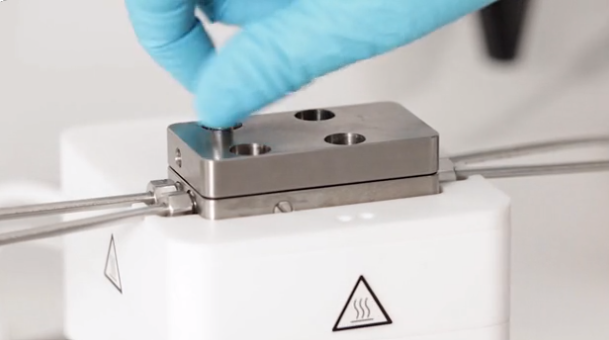

QSense High Pressure

The system provides you with the opportunity to study molecular interactions at surfaces and interfaces in real-time, exploring real-life conditions of high pressure and high temperature in your experimental set up.

phenomena

-

Adsorption

-

Desorption

-

Binding and interactions

-

Swelling

-

De-swelling, crosslinking and collapse

-

Degradation, corrosion and etching

Measure in High Pressure & Temperature

Key features

-

Measure mass, thickness, and viscoelastic properties of rigid and soft films

7-harmonic QCM-D with QSense Decay technology enables qualitative and quantitative analysis -

High temperature chamber

Measure up to 150°C -

Maintain liquid phase

Use pressure to maintain liquid state in higher temperatures -

High pressure module

Measure between 90-200 bar to explore real-life pressure conditions -

Full high pressure set up

All you need to be able to work with liquid flow at high pressures -

Broadest offer of sensor surfaces and coatings

Set up model systems that are as close as possible to real-world conditions

QSOFT AND DFIND SOFTWARE

QSense software is tailored to help you maximize the potential of your QCM-D measurements. With QSoft capturing your data and Dfind simplifying your analysis, you can streamline your research process effortlessly.

measurement conditions

-

Flow mode

-

Stagnant mode

-

Liquid phase

-

Harsh chemicals

-

Low temperature

-

High temperature

-

Variable pressure

A closer look

Let's dive into the specifications for QSense High Pressure.

Measurement range and capacity

| Measurement channels | 1 |

| Working temperature* | 4 to 150 °C, controlled via the software, stability ± 0.02 °C |

| Working pressure | 90 to 200 bar (with the alternative peristaltic pump measurements can also be performed at ambient pressure) |

| Sensors (frequency range) | 5 MHz (1-72) |

| Number of measured harmonics |

7, allows for full viscoelastic modeling |

Sample and fluidics

| Minimum sample volume, stagnant mode | ~ 40 μl |

| Minimum sample volume, flow mode | ~ 200 μl |

| Flow rates | 25-150 μl/min applicable for QSense setup (Peristaltic pump settable to 0-1 ml/min) |

| Additional info | Note that the system liquid to be used in the QSense High Pressure System may require a fume hood or point exhaustion |

Performance characteristics

| Maximum time resolution | 300 datapoints per second (each datapoint represents an f and D value) |

| Sensitivity/limit of detection and noise | Refer to performance in different modes, for more info visit QSense Explorer product page |

| Long-term stability* | Frequency: < 1 Hz/h Dissipation: < 0.15∙10-6 Temperature: < 0.02˚C/h |

*The temperature stability depends on variations in how the ambient affects the warming or cooling of the chamber. The specified temperature stability may not be reached if the room temperature changes more than ± 1° C, if there is a draft or a heat source nearby. The specifications above are valid for this configuration. All specifications are subject to change without notice.

QSoft and Dfind software

QSense softwares are designed for you to make the most out of your QCM-D measurements. QSoft is collecting your data whereas Dfind makes your analysis easier.

Dfind features

Computer requirements

Required

- PC with 64-bit Windows 7 SP1, 8, 8.1 or 10

- At least 1366×768 px screen resolution

- At least 4 GB RAM

Recommended

- 1920×1080 Full HD screen resolution.

- At least 8 GB RAM

- At least 50 GB HD space

- Core i5 5th generation Intel (or comparable) processor or better

Electrochemistry Module

For simultaneous QCM-D and electrochemistry measurements on the same surface. Enables cyclic voltammetry and electrochemical impedance measurements to explore polymer behavior, electrostatic interactions, corrosion etc.

Ellipsometry Module

Enables simultaneous QCM-D and ellipsometry measurements on the same surface, which allows for quantification of solvent content in the film. It also gives a refined analysis of the morphological changes of the adsorbed film.

Window Module

The Window Module allows optical access to the sensor surface through a sapphire window. It enables experiments with UV-induced reactions and when used in the QSense Explorer chamber, the compact design also enables microscopy studies of reactions on the sensor.

What our customers say

Our instruments are present at many prestigious universities and research facilities worldwide. Take a minute to find out what others say about QSense High Pressure.

Prof. Dennis R. Heldman, The Ohio State University

"Our laboratory uses the QSense High Pressure QCM-D system for the study of the reactions occurring at the interface between a surface and a high-protein liquid food. Information about the rate of fouling on the surface and the composition of the foulant has provided new and important insights before scale-up to pilot and commercial-scale experiments with a focus on the contributions of flow characteristics over the surface. These new and different insights provide our laboratory and others with a completely new and different dimension to our research.”

The Ohio State University

Ohio State University, OSU, is the highest-ranked public university in Ohio and home to the Department of Food Science and Technology. The work of Prof. Dennis R. Heldman centers around food engineering, with emphasis on process design to achieve maximum efficiency and optimum food product quality.

Learn more

We have gathered all our in-depth knowledge associated with QSense High Pressure. Browse around amongst guides, overviews and white papers to find a topic of interest.

- QSense

How Excipients, Surfaces and Formulation Conditions Affect Therapeutic Proteins

- QSense

Basics of QCM-D

- QSense

How to Optimize the QCM-D Baseline Stability

- QSense

The Working Principles of QCM and QCM-D

- QSense

QCM-D vs other QCMs

- QSense

What is Piezoelectricity?

- QSense

How QCM Results are Influenced by Layer Distribution

- QSense

Why the Resonance Frequency of a QCM Sensor is 5MHz

- QSense

Characterization of Polymer-based Systems

- QSense

Using QCM-D in the Food Industry

- QSense

What is Biocompatibility?

- QSense

Why it is Useful to use Multiple Overtones in QCM Measurements?

- QSense

Nanocellulose Research with QCM-D

- QSense

Analysis of Surfactant-Surface Interactions with QSense

- QSense

Getting Started with QSense Dfind

- QSense

QCM-D Data Analysis

- QSense

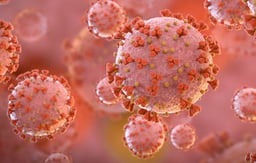

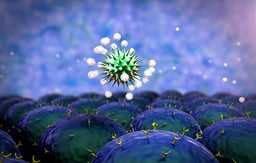

QCM-D as a Tool to Study the Binding of Viruses

- QSense

Characterization of Surfaces and Surface Reactions in Energy Storage

- QSense

QSense Etching Guide

- QSense

QCM-D Characterization of Antimicrobial Lipid Interactions with Supported Lipid Bilayers: Towards Antiviral Applications in the Biomedical and Agricultural Sectors

- QSense

The Sauerbrey Relation

- QSense

QCM-D Studies of Engineered Nanoparticles

- QSense

Characterization of Biomolecular Interactions

- Attension

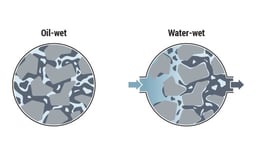

Working with QCM-D and Contact Angle Measurements under High Pressure - Oil and Gas Applications

- QSense

Adsorption and Aggregation of Monoclonal Antibodies at Silicone Oil-Water Interfaces

- QSense

QSense Analysis in CMP

- QSense

The Dissipation Factor in QCM-D Technology

- QSense

Temperature Stability in QCM Measurements

- QSense

What is Dissipation?

- QSense

What is a Viscoelastic material?

- QSense

How to Generate Quality QCM-D Data

- QSense

QCM-D vs other QCMs

- QSense

QCM-D Publications in Battery Research

- QSense

How to read a QCM Specification

- QSense

Dfind Basic Training Course

- QSense

Information Obtained with QSense QCM-D

- QSense