A water break test is a commonly used method to check the surface cleanliness in the industry setting. The main purpose of the test is to evaluate whether the surface is ready for the next process step, the most typical being application of coating. The test, however, has several limitations which make it highly user-dependent, and the traceability of the test results is not possible. For this reason, other tests for cleanliness are looked after.

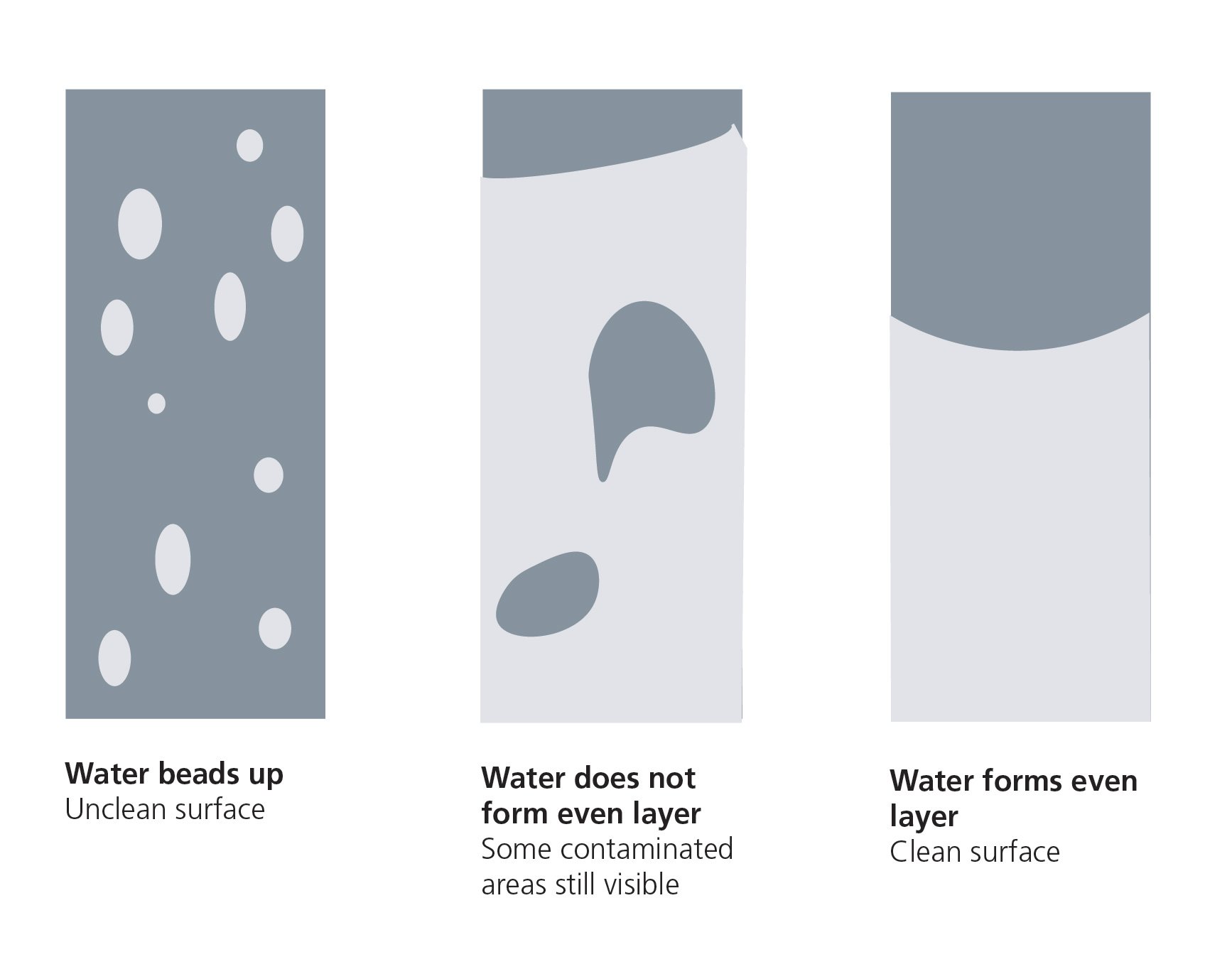

The water break test is performed by placing the surface to be tested in a vertical, or slightly angled position, depending on the testing protocol followed. Then, a mist of water is sprayed on the surface. The behavior of the water mist is then evaluated visually.

Contamination is typically oil-based, and thus hydrophobic. When the surface is not cleaned and there is contamination present, the water beads up on the surface. If water forms an even layer, the surface is considered clean, and the next process step can be conducted. In case, the surface is partially clean, the water might form even layers on some parts but show large pinholes in others. This will diminish adhesion in the contaminated areas and further cleaning should be performed. There are some variations on how to interpret the test results. In some cases, the break in the water layer at any given time is interpreted as the surface being unclean. In other instances, a certain time frame during which the breakage should happen, for example, 10 s, is specified.

These different ways of interpreting the results and the fact the method is based on visual observation make the method subject to personal judgment. This is not ideal when processing decisions are being made.

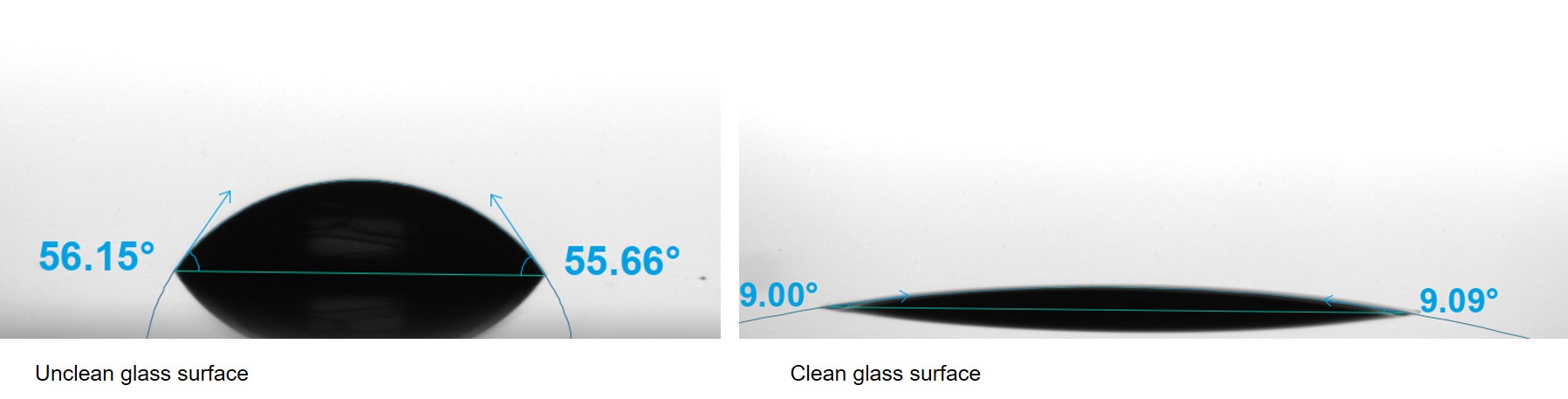

The water contact angle is a quantitative measure of wettability, and thus a great tool to evaluate surface cleanliness. Water contact angle measurement is done by placing the drop on the surface. The software will automatically analyze the drop and record a contact angle value. There are several advantages over the water break test. Contact angle measurements can be done automatically with very limited user interaction. The drop creation, placement, and analyzes can be completely automated. It is also possible to map the surface automatically so that several contact angle measurements are done on different parts of the surface. As contact angle is a quantitative measurement, there is no room for personal judgment, and the results can be saved in case there is a need to revisit them at a later state.

If you would like to see how contact angle measurement can be used for quality control purposes for good wettability and adhesion, please watch the webinar through the link below.