There are two main types of membranes: hydrophilic and hydrophobic. But what does that mean? And what are the differences between the two? Hydrophilic membranes are attracted to water, while hydrophobic membranes repel it. This difference in wettability is key in determining how each membrane is used. Hydrophilic membranes are often used in water filtration, while hydrophobic membranes are more common in oil and gas applications. Keep reading to learn more about these important types of membranes!

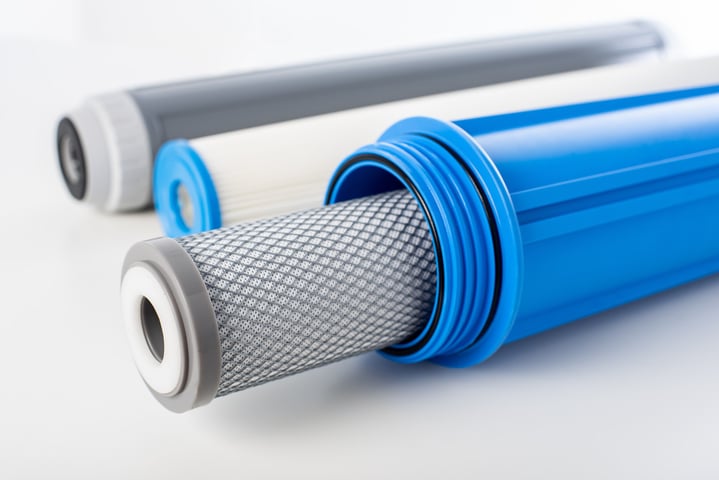

The wettability of a membrane is determined by its chemical composition. Hydrophilic membranes are typically made of materials like hydrophilic polymers such as nylon or polyethersulfone (PES). Other possible materials are inorganic silver and ceramics. A wide selection of materials is needed as the applications for hydrophilic membranes range from different biological sample filtrations to the food industry. Hydrophilic membranes are often used in reverse osmosis (RO) systems. RO systems use pressure to force water through a membrane, leaving contaminants behind. The contaminants are then flushed away, leaving clean, filtered water on the other side.

Hydrophobic membranes are usually made of hydrophobic polymers such as polytetrafluoroethylene (PTFE), or ceramics that need to be chemically treated to achieve hydrophobicity. In addition, the membrane surface can be roughened to enhance hydrophobicity. There are many applications for hydrophobic membranes such as filtration, gas separation, membrane gas adsorption, membrane distillation, and more that cannot be done with hydrophilic membranes.

As the wettability of the membrane has a crucial role, it is often studied with contact angle measurements. To read more about contact angle measurements, download the white paper through the link below.

Learn how to use contact angle measurements to evaluate surface cleanliness on different materials and link cleaning steps to reliable adhesion and coating quality.

Learn how wettability, surface free energy and surface roughness define paper and paperboard surface properties – and how to measure them for reliable print, coating and sealing performance.

Smart materials are materials that sense a change in their environment and respond in a useful, reversible way.

Discover how contact angle measurements help optimize plasma treatment for improved wettability and adhesion in industrial applications.

Discover why contact angle is essential for adhesion, coatings, and quality control. Learn how surface wettability impacts product performance.

Discover why PFAS-free coatings are needed, the challenges they present, and key strategies for developing high-performance alternatives.

At the heart of droplet formation are two key molecular forces: cohesion and adhesion.

Contact angle measurements provide a golden standard for evaluation of surface properties for quality control.

Contact angle is the angle a droplet forms in contact with a solid surface. Thermodynamically, it is a balance between cohesive and adhesive forces.