Food packaging plays a crucial role in the food industry. To maintain the quality and to ensure the safety of the food, food packaging should have certain required properties such as non-toxicity and chemical and thermal resistance. One of the main challenges of food packaging is the tendency of food to interact and adhere to the packaging, which often affects the quality, appearance, and shelf life of the food. A product’s higher affinity to its packaging can also lead to enhanced oxidation and adsorption of off flavors, resulting in unnecessary food waste. The surface properties of the package play a role in the interaction process. Then, on the other hand, printing on food packaging is often done which gives another set of requirements for the package.

The amount of adhering depends on the intermolecular interactions between the food and the packaging material. In general, the more hydrophobic the material is, the fewer interactions there are between a solid and a liquid. Therefore, many food packaging materials, such as packaging films, are made of hydrophobic, low-surface energy materials.

On the other hand, to improve the printability and sealing ability of plastic materials, it is often necessary to increase the wettability. This can be achieved through various surface treatments, such as corona discharge treatment (CDT). CDT is a commonly used method to introduce polar groups onto the material surface, resulting in improved adhesion and printing properties.

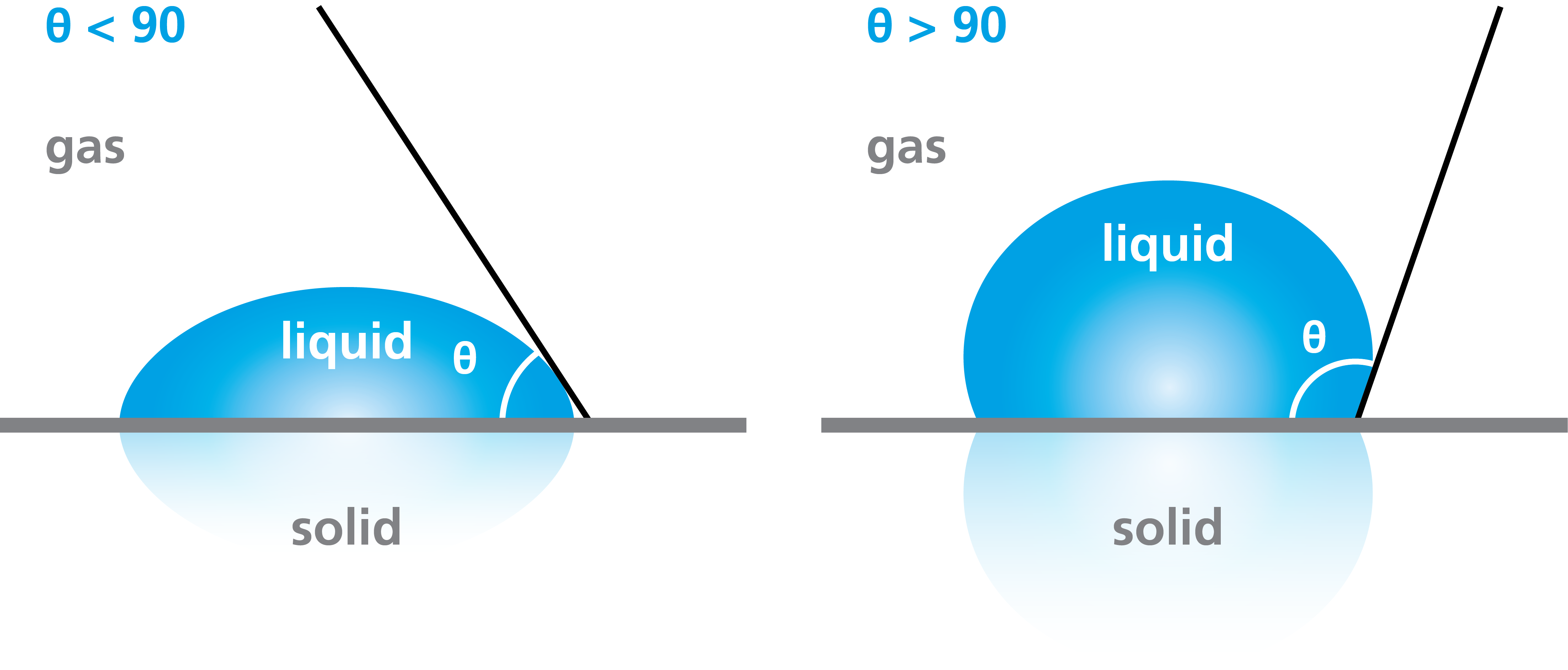

Contact angle measurements provide a fast and convenient tool to analyze the wettability behavior of the packaging material as well as to predict the successfulness of a surface treatment. Water contact angle measurements are used to determine the hydrophilicity or -phobicity of the surface. When a water contact angle is below 90 degrees, the surface is hydrophilic. Hydrophobic surfaces have a contact angle above 90 degrees.

If you would like to learn more about contact angle measurement and how it can be used to predict adhesion, please watch the webinar through the link below.

Learn about the effect of surface roughness and wettability on biocompatibility of biomaterials and medical devices.

This blog post describes the importance of fiber diameter on the contact angle measurements of fibers with Wilhelmy method

Standard contact angle measurement considers the surface's chemical properties. The influence of surface roughness is added by utilizing the Wenzel equation.

Wettability is crucial in biomedical applications as it affects protein adsorption, cell adhesion, blood coagulation, and bacterial colonization.

Liquids’ ability to wet a solid surface has widespread importance in many everyday products and industrial processes.

Membrane wettability is a key property to ensure success of membrane distillation process

Wettability is pivotal in pharmaceutical dosage form manufacturing as well as in drug efficacy.

Understanding the wettability of membranes is essential for optimizing these processes and achieving desired separation outcomes.