Different types of surface treatments are commonly used to ensure suitable material properties for bonding, coating application, or printing. Good wettability is mandatory for good adhesion. The main purpose of the surface treatment is to increase the wettability of the surface and thus make it ready for the subsequent process. Quality control is needed to detect any possible problems in the surface treatment process early on and contract angle measurement provides an excellent tool for that.

Surface treatments are used to modify the wettability of the surface. This is done by either changing the surface chemistry, surface topography, or both.

Surface treatments such as plasma and flame treatments are especially utilized for modification of polymer surfaces which are inherently hydrophobic and thus their wettability is low. The main mechanism of the wettability improvement in plasma treatment of polymers is thus the change in surface chemistry. During plasma treatment, the high-energy surface groups are formed due to reactions between the plasma species and the native surface groups of the polymer.

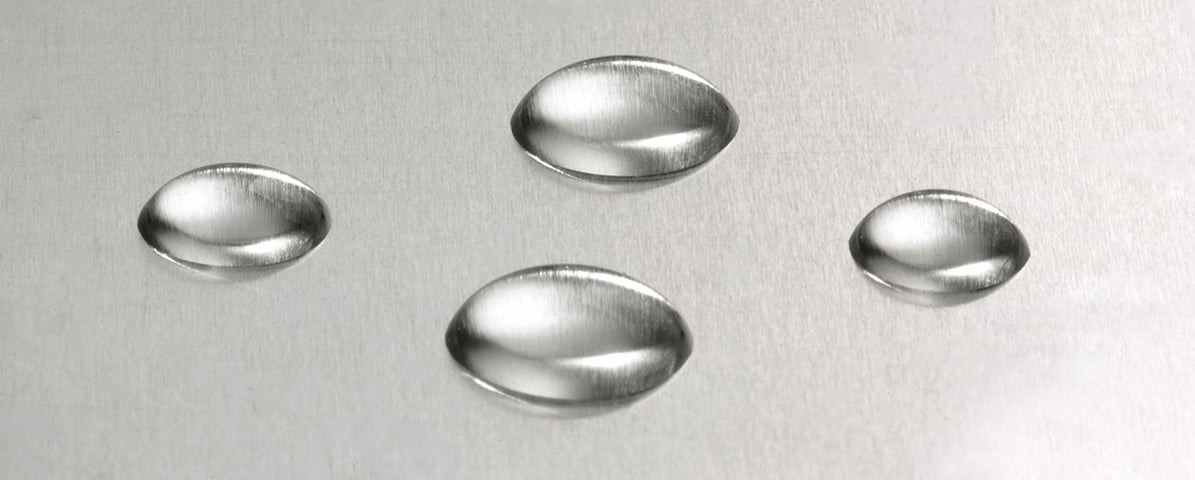

For metals, the main purpose of the surface pre-treatment is to clean the surface and remove the possible native oxide layer. In addition, increasing the surface roughness has a favorable effect on metal wettability. As native metal surface typically has a contact angle well below 90 degrees, adding surface topography will further decrease the contact angle and thus increase the surface wettability.

As pre-treatment is typically mandatory for good adhesion, it is important to check that it has been successful. This increases the chance to catch any possible problems early on in the process.

The contact angle is a measure of wettability and thus it is a natural choice for such a measurement. In addition, contact angle measurements are fast to perform and are non-destructive which makes them especially suitable for quality control purposes. Contact angle measurements can also be performed in a small area which is important in applications where localized pre-treatments are needed, such as in electronics.

Additional benefits of the contact angle measurements include their traceability as modern instruments can store all the valuable information such as temperature and humidity for your records.

To learn more about quality control of surfaces and the instrumentation used, please watch the recorded webinar through the link below.

Learn how to use contact angle measurements to evaluate surface cleanliness on different materials and link cleaning steps to reliable adhesion and coating quality.

Learn how wettability, surface free energy and surface roughness define paper and paperboard surface properties – and how to measure them for reliable print, coating and sealing performance.

Smart materials are materials that sense a change in their environment and respond in a useful, reversible way.

Discover how contact angle measurements help optimize plasma treatment for improved wettability and adhesion in industrial applications.

Discover why contact angle is essential for adhesion, coatings, and quality control. Learn how surface wettability impacts product performance.

Discover why PFAS-free coatings are needed, the challenges they present, and key strategies for developing high-performance alternatives.

At the heart of droplet formation are two key molecular forces: cohesion and adhesion.

Contact angle measurements provide a golden standard for evaluation of surface properties for quality control.

Contact angle is the angle a droplet forms in contact with a solid surface. Thermodynamically, it is a balance between cohesive and adhesive forces.