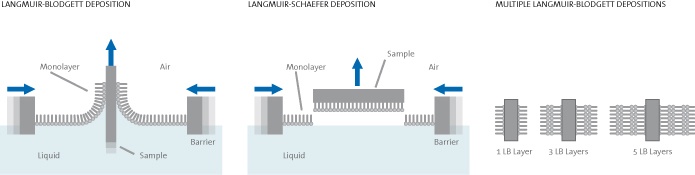

Coatings and thin films made from nanoparticles (NPs) have gained recognition and use in various products and applications including displays, sensors, medical devices, energy storage devices, and energy harvesting. Synthesis methods for nanoparticles [1] are already relatively well known, but to be able to utilize them in the applications mentioned above, NPs need to be transferred from the solution phase to a substrate’s surface – often as a monolayer or defined thickness multilayer. For this, controlled deposition methods are required. Langmuir-Blodgett and Langmuir-Schaefer provide a highly controlled method for nanoparticle monolayers at the air-liquid interface and their subsequent transfer onto a solid substrate. These methods can form high-density (poly-crystalline) monolayers on a wide variety of solid substrates, including conventionally challenging non-flat surfaces.

Techniques that enable such control and precision during thin film formation are critically important in the development of new nanoparticle-based materials. The Langmuir-Blodgett (LB) deposition method offers a combination of controlled deposition, a wide range of substrates, and usability in ambient conditions. In an LB deposition process, a nanoparticle suspension is first deposited at the air/water interface, then, the resulting film is compressed to the desired surface pressure and particle density and then transferred onto a solid substrate by dipping the substrate into and through the particle layer. The deposition can then be repeated to fabricate alternating layer structures or performed at different speeds and temperatures.

As a summary, with LB and LS methods, it is possible to:

The blog post was published for the 1st time on the 23rd of March 2017 and has since been updated.

Prof. Federica Sebastiani uses QCM-D to study the binding affinity of serum proteins to mRNA-LNPs. Here she explains what LNP:s are.

Sign upp for the webinar to learn more about how QCM-D is used to study biomaterial-induced activation of the immune system

Read about how QSense QCM-D analysis is used to investigate the effect of airborne Palladium nanoparticles on human lung cells, endothelium and blood.

Nanomaterials have found their way into ordinary products such as foods, cosmetics, and sportswear. Why did ‘nano’ become so popular? And what risks are involved when getting exposed to these nanoengineered entities?

Here we list 10 methods that can be used to characterize the nanoparticle chemical composition.

To avoid potential adverse effects, it is relevant to study how nanoparticles interact with their surroundings. Here we present examples of how nanoparticle interaction with a variety of surfaces can be analyzed.

Nanoparticle size is one of the key parameters that are relevant to characterize in nanoparticle suspensions. Here we list six different methods that you can use to characterize the nanoparticle size.

Nanoparticle suspensions are complex systems and their characterization includes several parameters such as size, concentration in solution, shape, surface charge and chemical composition. Here we provide a list of methods that could be used to characterize nanoparticle suspensions.