The traditional way of testing etching and corrosion is to repeat a number of wash cycles and thereafter visually inspect the object for etching effects. Sometimes, as many as 70 wash cycles may be required to detect and evaluate the etching. This is both costly and time-consuming but there are faster ways. Here we present a method that will help you assess the etching effects in one single wash cycle and in less than an hour.

QSense® technology is a method that can monitor surface etching with high resolution in a time-resolved manner. Thanks to the nanoscale sensitivity of this technology, removal of surface material can be detected and quantified in a single wash cycle.

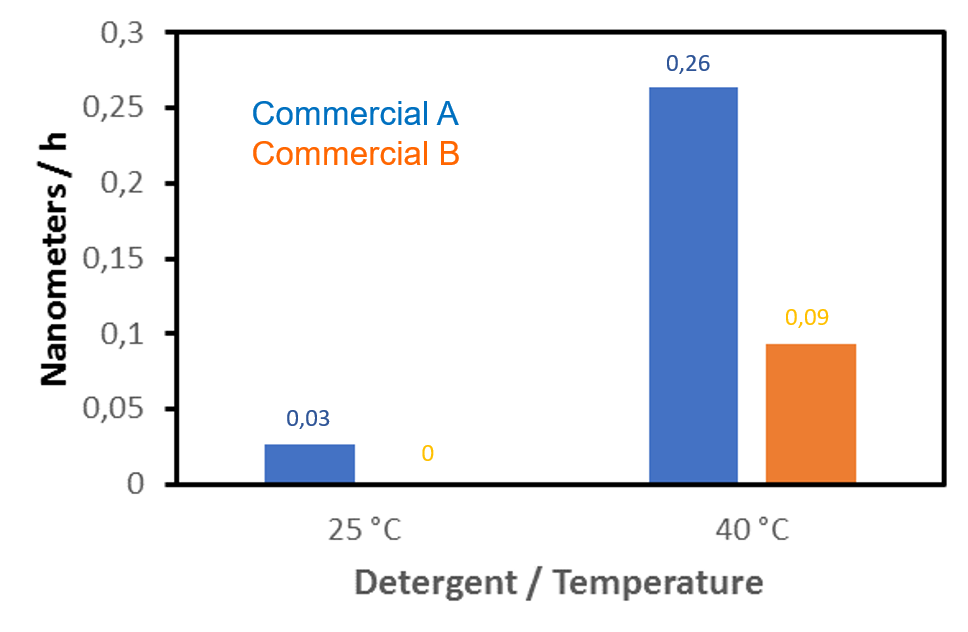

As an example, let us look at an assessment of the etching of two commercial detergents. Using a fully automated QSense instrument, the etching properties of detergent A and detergent B on soda lime were evaluated. Two different temperatures, 25 and 40°C, were tested and Swedish tap was used as a control. The 50-minute long wash program, used in the test, consisted of a 30-minute wash step and a 20-minute rinse step where Swedish tap water was used.

After the test, the etch rate during the detergent exposure was extracted, and the average surface removal was calculated as thickness removed per hour measured in nanometers.

The results, Fig. 1., show that the etching was both detergent and temperature dependent. Detergent A showed higher etching than detergent B at both temperatures and the etching increased with the temperature for both detergents. The control measurement showed no surface removal at neither 25 °C nor 40 °C.

Figure 1. Etching results for two commercial detergents, detergent A and detergent B, evaluated at two different temperatures, 25°C and 40°C, using QSense technology

Etching assessments can be very time-consuming, and they often involve an element of subjective nature, for example, grading by visual inspection. QSense technology offers both fast and objective quantification of etching effects. The method enables single point etching data, for a given surface and temperature, to be collected within one hour.

Download the guide to learn more about the procedure for evaluation of detergent etching properties using QSense technology.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Learn how QSense QCM-D analysis can reveal membrane fouling dynamics and optimize cleaning strategies for more efficient water treatment

Discover how QCM-D enables real-time cleaning analysis and reveals surfactant performance to optimize cleaning product development

Explore QSense QCM-D sensors to optimize cleaning efficiency with real-time insights, enhancing formulations and protocols across various conditions.

Discover how QSense QCM-D technology reveals real-time cleaning insights. Join our webinar to enhance your cleaning strategies and efficiency.

QSense QCM-D technology enables analysis of cleaning process dynamics, surface etching, and surface residual

Cleaning product performance assessments can be time-consuming, but with the right approach, evaluation and ranking can take less than one hour.

Read about the different components in cleaning products and how they work on a molecular level.

Eva Ekerot is the Marketing and Communications Director for QSense. She has a background managing numerous product portfolios within the medical technology and analytical instrument industries. She is devoted to user-driven development of high-tech products. More user-friendly technology is accessible to more people!