Throughout the cleaning product life cycle, ranking of performance is an important type of assessment. It is also a type of assessment that can be quite time-consuming. With the right approach, however, it is possible to evaluate and rank the product performance in less than one hour. Here we tell you how.

A drawback with many of the analysis methods that are traditionally used to assess cleaning product performance is that they are quite time-consuming. Typically, these methods are based on before-and-after comparison, i.e., the level of surface soiling is compared before and after the wash step where the surface is exposed to detergent solution. A faster way to rank the product performance is to run the wash step and the result assessment at the same time, rather than in sequence. This can be done with real-time surface analysis methods which measure the soil removal when the soil is exposed to the cleaning agent. Combining the wash step and result analysis makes the assessment less time-consuming than if the steps had been executed one at a time.

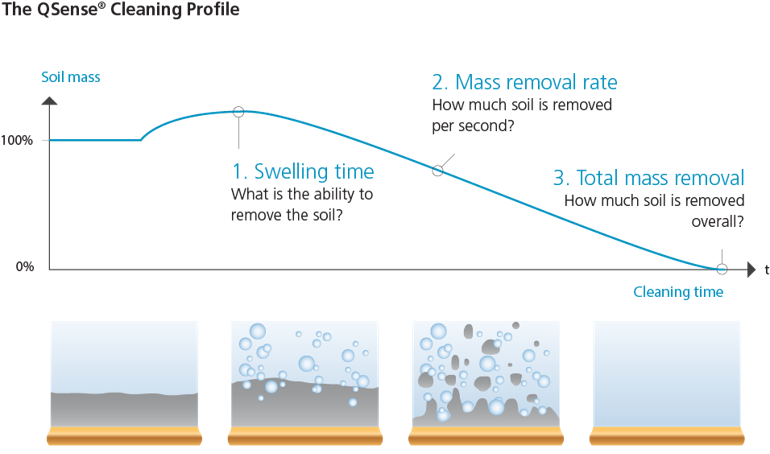

As an example, let us look at detergent efficiency evaluation by the QSense® technology. This technology measures changes of mass at the surface, i.e., it detects if, and how fast, the soil is dissolved and removed from the surface, Fig. 1.

During the cleaning step, the soil removal result is presented in real-time. This means that samples run in parallel can qualitatively be compared already during the wash step. From the cleaning profile data, information on i) soil swelling time, ii) soil mass removal rate, and iii) total mass removal is obtained, Fig. 1. Combined, this information will assign a performance score to each product candidate. The assigned score allows for them to be ranked and compared.

Figure 1. (Bottom) From left to right, a schematic illustration of a soiled QSense sensor which is exposed to the cleaning solution to be evaluated. The illustrations show how detergent penetrates the soil, which then swells and dissolves. In the illustration to the very right, the soil has been completely removed, leaving a clean sensor surface. (Top) The graph shows the cleaning profile of the detergent that is analyzed. The mass changes as a function of time reflect dynamic changes of the soil status and reveal the soil swelling, dissolution, and removal. Measuring the mass changes, the cleaning product performance can be assessed and compared with other candidates already during the wash step. The performance ranking is then obtained via the cleaning profile performance score.

Traditional methods used for cleaning product performance assessment are typically based on before-and-after comparisons and the assessment can be quite time-consuming. Using a time-resolved analysis method, such as QSense QCM-D, where the cleaning step and the data capture are performed simultaneously, the total assessment time can be shortened. A typical measurement setup, execution, and ranking assessment using QSense technology and cleaning profile analysis typically takes less than one hour. As the soil removal data is displayed in real time, an indication of the performance can be obtained already during the measurement.

Download the guide to read more about the detergent product performance evaluation and the cleaning profile analysis.

.

Editor’s note: This post was originally published in Dec 2018 and has been updated for comprehensiveness.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Learn how QSense QCM-D analysis can reveal membrane fouling dynamics and optimize cleaning strategies for more efficient water treatment

Discover how QCM-D enables real-time cleaning analysis and reveals surfactant performance to optimize cleaning product development

Explore QSense QCM-D sensors to optimize cleaning efficiency with real-time insights, enhancing formulations and protocols across various conditions.

Discover how QSense QCM-D technology reveals real-time cleaning insights. Join our webinar to enhance your cleaning strategies and efficiency.

QSense QCM-D technology enables analysis of cleaning process dynamics, surface etching, and surface residual

Read about the different components in cleaning products and how they work on a molecular level.

Soil removal efficiency of a formulation is typically assessed by running a cleaning test followed by an analysis of the result. Here we show how these two steps can be run simultaneously.

Eva Ekerot is the Marketing and Communications Director for QSense. She has a background managing numerous product portfolios within the medical technology and analytical instrument industries. She is devoted to user-driven development of high-tech products. More user-friendly technology is accessible to more people!