Contact angle hysteresis (CAH) is an important physical phenomenon. It is present in nature but also plays a role in many industrial processes. When you look through the window on a rainy day, you have probably noticed that some of the water droplets stick to the glass even though gravity is pulling them down. The phenomenon can be explained by contact angle hysteresis. CAH is also important in industrial processes such as immersion lithography, fiber coatings, and ink-jet printing. Measuring contact angle hysteresis can also provide additional information on your surface compared to the static contact angle alone.

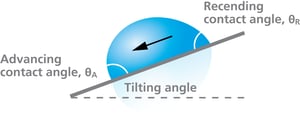

Contact angle hysteresis arises from the chemical and topographical heterogeneity of the surface, or swelling, rearrangement or alteration of the surface by the solvent. Contact angle hysteresis cannot be measured directly but through the measurement of advancing and receding contact angles. Let’s think about the droplet of water on a tilted surface. If there would be no contact angle hysteresis, the drop would immediately, when hitting the surface, start to slide on it because gravity is pulling it downwards.  However, the contact angle hysteresis causes some drops to stay even on a vertical surface, such as a window glass. When tilting of the surface is increased (or raindrop size on a window glass increases) at some point the gravity will win and the droplet starts to move. At this point, the advancing and receding angles can be measured. Advancing contact angle tells the maximum contact angle the surface can have and the receding contact angle the minimum.

However, the contact angle hysteresis causes some drops to stay even on a vertical surface, such as a window glass. When tilting of the surface is increased (or raindrop size on a window glass increases) at some point the gravity will win and the droplet starts to move. At this point, the advancing and receding angles can be measured. Advancing contact angle tells the maximum contact angle the surface can have and the receding contact angle the minimum.

To understand how contact angle hysteresis can be utilized in coating development, please download the case study below.

Receding contact angle is the lowest possible contact angle on a given surface. Receding angle is measured on previously wetted surface.

Contact angle hysteresis can tell you about the homogeneity of your surface coating.

One should always measure the advancing and the receding contact angle to get the true picture of the surface wettability.

Due to a wide range of applications, the measurement of wettability, i.e., the contact angle measurement can be done with several different methods.

More and more research interest is being put on functional coatings. New measurement techniques are required to evaluate them.

Contact angle hysteresis is often measured with so-called tilting cradle or plate method. The measurement can be done either manually or automatically.

Dynamic contact angle measurements with the needle method has been automated for reliable and repeatable results.

Contact angle hysteresis can be measured with optical (needle and tilting methods) and force (Wilhelmy method) tensiometers.