Contact angles are routinely measured both in academia and industry as they offer simple yet extremely sensitive measurement methods for surface characterization. Contact angle tells about wetting of the surface which can be related to adhesion and cleanability for example. Although, a static contact angle is an excellent tool in many cases, a more in-depth understanding of the surface properties requires other methods.

Static contact angle measurements can sometimes be problematic. The main reason for this is that there is not just one but several seemingly stable contact angles that could be measured on the same surface. In practice, this could be seen in contact angle readings varying from measurement to measurement. When placing the drop on the surface, the drop can take any of these seeming stable contact angle values. If the measurement parameters, i.e. volume of the drop and the way the drop is placed, for example, are kept the same it is still possible to get quite repeatable results. However, the static contact angle is not able to tell you the true nature of your surface. Even if you can repeat the measurements, it doesn’t prove that your surface is homogeneous and smooth, it just tells you that your measurement protocol is repeatable (which is of course good on its own!).

What can help you analyze your surface more in-depth, is the measurement of contact angle hysteresis. Contact angle hysteresis can be calculated by measuring the advancing and receding contact angle. The advancing contact angle is the highest possible contact angle on the surface and receding the lowest possible. All the seemingly stable static contact angle values fall in between these two. Contact angle hysteresis is the difference between the values. An ideal surface, i.e. surface which is chemically homogeneous and smooth to the atomic level, doesn’t have any contact angle hysteresis. In real life, such a surface doesn’t exist, and contact angle hysteresis is always present.

In real-life applications, contact angle hysteresis can tell you about the homogeneity of your surface coating. If contact angle hysteresis is large (i.e. ten(s) of degrees), the coating has probably some chemical or roughness-related inhomogeneities, most typically both. In practice, the static contact can remain at a high level but the coating degradation can be seen from the increasing contact angle hysteresis.

Different types of hydrophobic and superhydrophobic coatings are gaining interest due to their ability to prevent dirt and dust accumulation.

Hydrophobic coatings on glass are especially interesting as glass is used in screens, windshields, and lenses to name a few. Contact angle measurements offer an excellent method to determine the quality of your coatings. However, sometimes the static contact angle alone is not able to distinguish the differences between different coatings. The dynamic contact angle can be used to gain additional information on the surface.

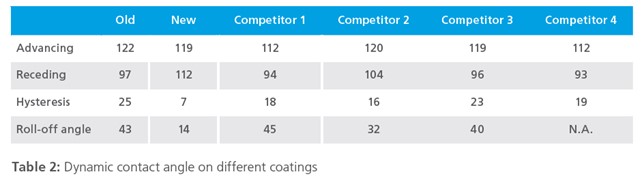

As a starting point, the new coating was shown to have superior behavior when compared to the old coating or those provided by competitors. However, static contact angle measurements were not able to provide much insight since the differences between the static contact angles were not significant.

To get more detailed information about the wetting behavior of the coatings, the dynamic contact angles, as well as roll-off angle, were measured. The measurements showed clear differences between the different coatings, the new coating proving its superiority against others.

To download the full case study, please use the link below.

Receding contact angle is the lowest possible contact angle on a given surface. Receding angle is measured on previously wetted surface.

One should always measure the advancing and the receding contact angle to get the true picture of the surface wettability.

Due to a wide range of applications, the measurement of wettability, i.e., the contact angle measurement can be done with several different methods.

More and more research interest is being put on functional coatings. New measurement techniques are required to evaluate them.

Contact angle hysteresis is often measured with so-called tilting cradle or plate method. The measurement can be done either manually or automatically.

Dynamic contact angle measurements with the needle method has been automated for reliable and repeatable results.

Contact angle hysteresis can be measured with optical (needle and tilting methods) and force (Wilhelmy method) tensiometers.

Contact angle hysteresis (CAH) is an important physical phenomenon. When you look through the window on a rainy day, you have probably noticed that some of the water droplets stick to the glass even though gravity is pulling them down. The phenomenon can be explained by contact angle hysteresis.