The distinction between biomaterials and tissue engineering is often diffuse and has changed over time. Here we explain the terminology and sort out how the two concepts relate to each other.

Regenerative medicine refers to methods and components to repair or replace lost or impaired body functions. Two major fields are biomaterials and tissue engineering (TE). In brief, biomaterials are man-made materials developed for, and used in, products intended for medical treatments. Tissue engineering, on the other hand, is a set of methods to produce living functional tissue from cell cultures or tissue seeds. Initially, TE was early on regarded as a subarea of biomaterials. The reason was that the scaffolds and templates used in TE, and the materials for them, were much in focus. Today TE is regarded as a field in its own right, overlapping with biomaterials primarily regarding the used, biocompatible, materials.

Products made from biomaterials cover a broad spectrum. One prominent example is medical implants, where familiar and clinically well-established products are artificial hip joints and other joint replacements, intraocular lenses, dental implants, cochlear implants, heart and aorta valves, stents for the repair of failed heart coronary arteries, vascular grafts, breast implants and many more. All of these are intended for more or less permanent use in the body. Biomaterials also include many components and devices that are used only temporarily like syringes, catheters, artificial skin for burn wounds, and some orthopedic repair components.

The material classes used for the implants and components cover the whole accessible range; metals, alloys, ceramic materials, polymers, carbon and combinations of them including composite materials. Biomaterials are sometimes called biocompatible materials (there are some minor distinctions not addressed here) to emphasize the functional requirements of biomaterials.

Biocompatibility means different things for different implants, but generally, it is the ability of a specific material to meet the functional requirement in a specific application. In orthopedic implants, the strength and other mechanical properties are key aspects, but also the ability of the material to integrate with bone tissue. In stents and vascular grafts and heart valves, blood compatibility is a crucial property to prevent blood clotting and its consequences. Blood compatibility is thus a key property for such devices.

As mentioned above tissue engineering was early on regarded as a subarea of biomaterials, which may sound surprising today, but is explained by the early emphasis on the materials in scaffold/templates/matrices used for TE.

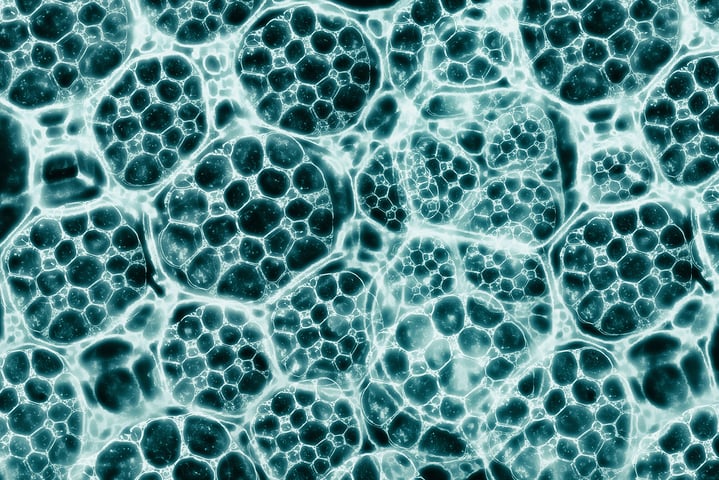

Contrary to the area of biomaterials, which refers to the actual material itself, tissue engineering is referring to the way of producing the tissue material. In fact, tissue engineering is a manifold of methods to grow tissues and/or organs for tissue/body repair and is, as mentioned above, also an important subfield of regenerative medicine.

The focus in tissue engineering today is on finding the right starting cell or tissue cultures, and then on offering the culture optimal development conditions, often in a bioreactor, which include biomolecular signal substances, nutrition, pH, temperature, scaffolds to hold and guide the structure, agitation/motion patterns and so on. Some tissues need vascularization, which is much more demanding than non-vascularized tissue. In order to get the right shape and design of the tissue/organ 2D and 3D printing are beginning to be popular.

From the above, it should be quite clear that the fields Biomaterials and TE are in fact very different in content and focus although there is some overlap and synergies regarding the materials used, and also regarding bio-interface processes.

Watch the webinar to learn more about biomaterials and tissue engineering

Learn about the effect of surface roughness and wettability on biocompatibility of biomaterials and medical devices.

Contact angle measurements help to evaluate the adhesion and performance of biomedical coatings.

Contact angle measurements offer insight into the behavior of a biomedical device in the human body.

Sign upp for the webinar to learn more about how QCM-D is used to study biomaterial-induced activation of the immune system

The concept of wettability, its importance in biomaterials, and how it can be manipulated to improve biocompatibility and overall performance are reviewed.

Read about how QSense QCM-D analysis is used in the quest to tackle inflammation and bacterial infections on implant surfaces.

Learn about the past and future development of biomaterials in regenerative medicine.

Learn more about how biocompatibility is defined and what this property entails

Bengt Kasemo was one of the co-founders of Q-Sense AB in 1996 and was on the Board of Directors of Q-Sense and Biolin Scientific AB for several years. Professor Kasemo's research projects focused on surface science, bio-interfaces, biomaterials, catalysis, nanotechnology, sensors and scientific instruments, nanotoxicology and nanosafety, as well as sustainable energy.