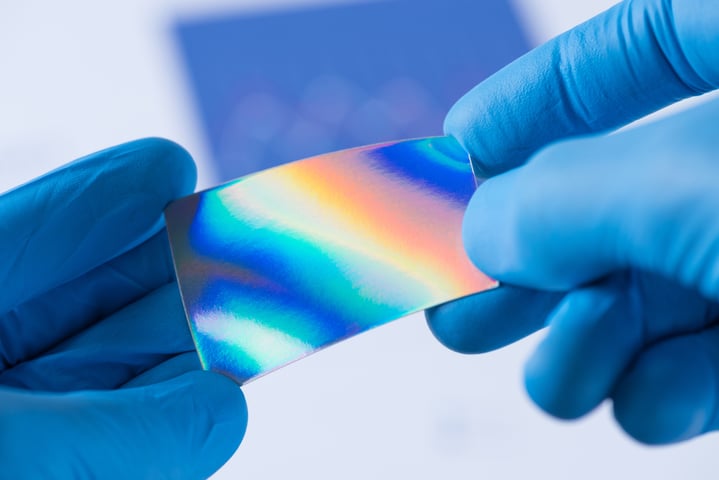

With the increasing interest towards nanoparticle thin films, there is a need for nanoparticle coating technique that can produce monolayers or controlled multi-layered structures on large areas. Spin coating is one of the most used thin-film coating technique and for this reason, any new technique is typically compared to it.

The most typical usage of spin coating is the deposition of photoresist in the semiconductor industry. A photoresist is a light-sensitive polymer compound dispersed into a solvent. The photoresist is dispensed on the substrate with the pipette. A uniform layer with the desired thickness is achieved by the combination of acceleration and constant speed rate sections in the pre-defined spinning recipe.

Langmuir-Blodgett method has traditionally been used to deposit different types of amphiphilic molecules such as phospholipids and fatty acids. There a monolayer of molecules is first spread on the air-water interface after which the packing density of the monolayer is controlled by decreasing the surface area. Finally, the monolayer is transferred to the solid substrate by dipping.

When it comes to nanoparticles, the Langmuir-Blodgett method offers many advantages over spin coating. First, due to the nature of the spin-coating technique, it requires relatively large amount of nanoparticle solution as some of it will be wasted in the process. In Langmuir-Blodgett method, practically all material can be utilized. Second, Langmuir-Blodgett also offers a well-controlled packing density of the nanoparticles and furthermore, the monolayer quality can be inspected prior the deposition with the technique called Brewster angle microscopy. Multilayer structures can also be produced easily as there can be as many dipping cycles as needed.

| Spin Coating | Langmuir-Blodgett | |

| Amount of material required | High | Low |

| Controlled packing density | No | Yes |

| Monolayer inspection prior deposition | No | Yes |

| Controlled multi-layer structures | No | Yes |

To read more about Langmuir-Blodgett deposition of nanoparticles, please download the white paper below.

Nanoparticle thin films are gaining recognition and use in various products and applications including displays, sensors, and energy storage.

LB films offer various opportunities for the creation of biosensors.

Roll-to-roll LB technology combines the benefits of Langmuir-Blodgett to high throughput and the possibility to use flexible substrates.

Nanoparticle thin films are finding applications in areas where functional coatings are needed. Dip coating offers one of the simplest methods to coat the substrate with nanoparticles.

Introduction to graphene and its deposition techniques

This blog shows that nanoparticle deposition can improve thin film solar cell efficiency.

Describes the most common nanolithography methods to produce nanosized features

Nanoparticle lithography is a promising fabrication technique. Unlike other techniques, it has a potential to be performed on curved surfaces.