A biosensor is a device that can detect the presence of a specific biological molecule or compound, such as a protein or hormone. Langmuir-Blodgett (LB) films are thin layers of material that can be used to create detecting layers on biosensors. LB films are created by depositing a thin layer of material onto a substrate, such as a glass or metal surface, using a technique called the Langmuir-Blodgett deposition process.

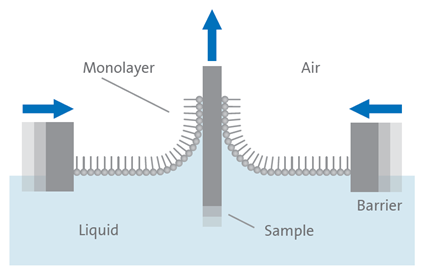

The LB film deposition process involves the transfer of material from a liquid surface, called a Langmuir film, onto a substrate. This process is carried out in a Langmuir-Blodgett trough, which is a specialized piece of laboratory equipment that consists of a liquid vessel and movable barriers.

To create an LB film, the material to be deposited is first dissolved in a solvent and spread over the surface of the water in the Langmuir-Blodgett trough.  The material forms a monolayer at the surface that can then be manipulated by moving the barrier across the surface of the water. Barriers are used to compress the monolayer and create a uniform film of material. Once the film has been formed, it can be transferred onto a substrate by carefully pulling or pushing the substrate through the interphase. This process can be repeated multiple times to create multilayer structures.

The material forms a monolayer at the surface that can then be manipulated by moving the barrier across the surface of the water. Barriers are used to compress the monolayer and create a uniform film of material. Once the film has been formed, it can be transferred onto a substrate by carefully pulling or pushing the substrate through the interphase. This process can be repeated multiple times to create multilayer structures.

LB films have several properties that make them useful for biosensor applications. They are highly uniform, with a well-defined thickness, and can be fabricated with a variety of materials.

LB films offer various opportunities for the creation of biosensors. Enzyme-based biosensors have been utilizing LB films for decades because their molecular structure is designed to maintain enzyme activity. These LB films can contain enzymes and be exposed to samples containing analytes that interact with the enzyme in a specific manner. In most cases, enzyme-based biosensors made with LB films consist of lipids that are arranged in monolayers or multilayers, which serve as appropriate matrices to safeguard or amplify enzyme activity.

[1] Miyahara, Y. et. al., "Micro urea sensor using semiconductor and enzyme immobilizing technologies", J. Chem. Soc. Jpn., 1983, 6, 823-830

[2] Pastorino, L. et. al., "Biocatalytic Langmuir-Blodgett assemblies based on penicillin G acylase", Colloids Surf. B. Biomembr., 2002, 23, 357-363.

[3] Girard-Egrot, A.P. et. al., "Enzyme association with lipidic Langmuir-Blodgett films: Interests and applications in nanobioscience", Adv. Colloid Interface Sci., 2005, 116, 205-225.

[4] Oliviera, O.N., et al.,"The past and the future of Langmuir and Langmuir-Blodgett films", Chem. Rev., 2022, 122, 6459-6513.

Nanoparticle thin films are gaining recognition and use in various products and applications including displays, sensors, and energy storage.

Roll-to-roll LB technology combines the benefits of Langmuir-Blodgett to high throughput and the possibility to use flexible substrates.

Spin coating is one of the most used thin-film coating technique and for this reason, any new technique is typically compared to it.

Nanoparticle thin films are finding applications in areas where functional coatings are needed. Dip coating offers one of the simplest methods to coat the substrate with nanoparticles.

Introduction to graphene and its deposition techniques

This blog shows that nanoparticle deposition can improve thin film solar cell efficiency.

Describes the most common nanolithography methods to produce nanosized features

Nanoparticle lithography is a promising fabrication technique. Unlike other techniques, it has a potential to be performed on curved surfaces.