A sensor can be defined as a device able to detect changes in the environment, convert that change to a signal and send it forward to be read by a person or an instrument. Sensors vary from very simple temperature sensors to complex electrochemical ones. Nanoparticle thin film-based sensors offer several advantages, such as better sensitivity and selectivity, over traditional sensor types, especially in electrochemical sensing. The main challenge has been the fabrication of the nanoparticle sensing layer. Two main methods have been used; layer-by-layer (LbL) and Langmuir-Blodgett (LB).

One of the main advantages of using nanoparticles (NP) as sensing element is that the size and surface characteristics of NPs can be affected during the preparation process. By fine-tuning the properties of the nanoparticles, high selectivity and sensitivity can be achieved. NPs also provide a large effective sensor surface area which can further increase the sensitivity.

The size and distribution of the NPs on a surface affect the performance of the electrochemical sensor. Pre-synthesised and functionalized colloidal nanoparticles are most typically used in sensor applications as they make well-defined depositions possible.

The layer-by-layer technique is a method where layers of different materials are successively deposited on the solid substrate, the simplest way to do that is by dip coating.

Let’s take a substrate that is initially positively charged. First, the substrate is immersed in the solution containing negatively charged species, which will adsorb on the substrate surface by electrostatic interactions. This will produce a negatively charged surface. The substrate is then immersed in the rinsing solution to get rid of loosely bound species to prevent contamination of the next solution. The substrate is then dipped into the solution containing positively charged species to generate a positively charged surface. This is followed by another rinsing step. This procedure can be repeated as many times as needed to build a desired multi-layered structure.

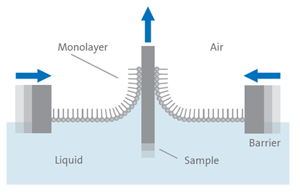

In Langmuir-Blodgett method, the deposition is started by the creation of a Langmuir monolayer. The Langmuir monolayer is formed by spreading species to be deposited on the air-water interface on a shallow trough. The trough contains barriers which can be moved in a controlled fashion to reduce the surface area of the interface and thus bring the species closer together.  When the desired packing of the species is achieved, the deposition can be done by withdrawing the substrate through the air-water interface. Multi-layered structures are also possible by repeating the process.

When the desired packing of the species is achieved, the deposition can be done by withdrawing the substrate through the air-water interface. Multi-layered structures are also possible by repeating the process.

Comparison of the LbL and LB

The main difference between the two techniques is the interface at which the deposition takes place. In LbL, the species to be deposited are dispersed into solution and the assemble happens at the solution- solid interface. On the other hand, in LB method, the deposited species are trapped at the air-water interface which is also where deposition takes place. Also, in LbL, the deposition is carried out through spontaneous adsorption process, whereas in LB the film components are well packed and structurally organized. The precise control over the packing density of the deposited film is the main benefit of the LB method.

The main benefit of the LbL is its simplicity. In principle, the method requires only tweezers and beakers although in practice more sophisticated and automated systems are often used.

As a summary, one could conclude that both methods have their strength and weaknesses and the decision on which method to use should be made according to the final requirement of the film structure.

If you are interested in reading more about nanoparticle assembly by Langmuir-Blodgett technique, please download the white paper below.

To see our nanoparticle coating solutions, go to the product page.

Nanoparticle thin films are gaining recognition and use in various products and applications including displays, sensors, and energy storage.

Describes the most common nanolithography methods to produce nanosized features

Nanoparticle lithography is a promising fabrication technique. Unlike other techniques, it has a potential to be performed on curved surfaces.