The surface is said to be hydrophobic when water beads up. The word hydrophobic can be directly translated as a “fear of water” which is a good description of a surface that repels water. Several examples of such surfaces can be found in nature such as lotus leaves, shark skin, and butterfly wings. Nowadays, hydrophobic coatings are used in many applications across several application areas.

Hydrophobic coatings are used in many consumers products. One of the easiest to relate to is outdoor clothing. Different clothing brands have their own version of hydrophobic coatings, but Gore-Tex is probably the best-known one. Gore-Tex material is based on thermo-mechanically expanded PTFE (polytetrafluoroethylene) and other fluoropolymers. Teflon is a brand name for PTFE, and Teflon cookware is another example of consumer products where hydrophobicity is important. The reason why PTFE repels water comes from the high electronegativity of the fluorine atoms. One problem with the hydrophobic coating is that it is prone to wear and tear. Clothes and cooking pans are washed which deteriorates the coating quality over time.

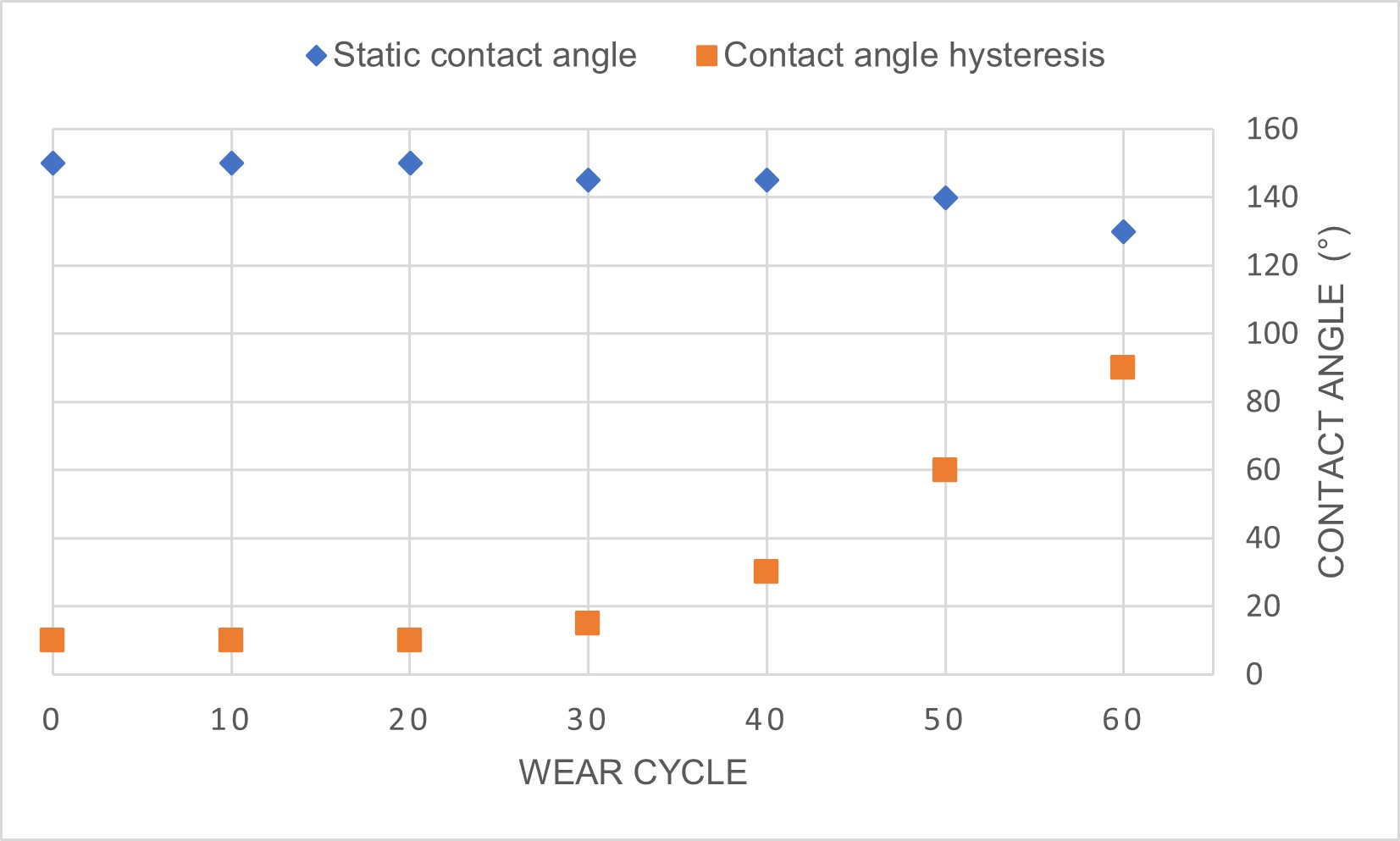

The durability of hydrophobic coatings is one of the biggest challenges. While the hydrophobic chemistry is now quite well understood, it is still a challenge to produce coatings that would tolerate wear and tear. One way to study this is through contact angle measurements. Depending on the surface studied, the wear could mean for example washing of the clothes or the frying pan. In all cases, what typically happens is that while the static contact angle stays fairly constant or decreases slightly over time, the major effect can be seen in contact angle hysteresis. High contact angle hysteresis indicates that the coating is no longer uniform and while droplets with high contact angles are still seen, they don’t roll off the surface as before.

Learn how to use contact angle measurements to evaluate surface cleanliness on different materials and link cleaning steps to reliable adhesion and coating quality.

Learn how wettability, surface free energy and surface roughness define paper and paperboard surface properties – and how to measure them for reliable print, coating and sealing performance.

Smart materials are materials that sense a change in their environment and respond in a useful, reversible way.

Discover how contact angle measurements help optimize plasma treatment for improved wettability and adhesion in industrial applications.

Discover why contact angle is essential for adhesion, coatings, and quality control. Learn how surface wettability impacts product performance.

Discover why PFAS-free coatings are needed, the challenges they present, and key strategies for developing high-performance alternatives.

At the heart of droplet formation are two key molecular forces: cohesion and adhesion.

Contact angle measurements provide a golden standard for evaluation of surface properties for quality control.

Contact angle is the angle a droplet forms in contact with a solid surface. Thermodynamically, it is a balance between cohesive and adhesive forces.