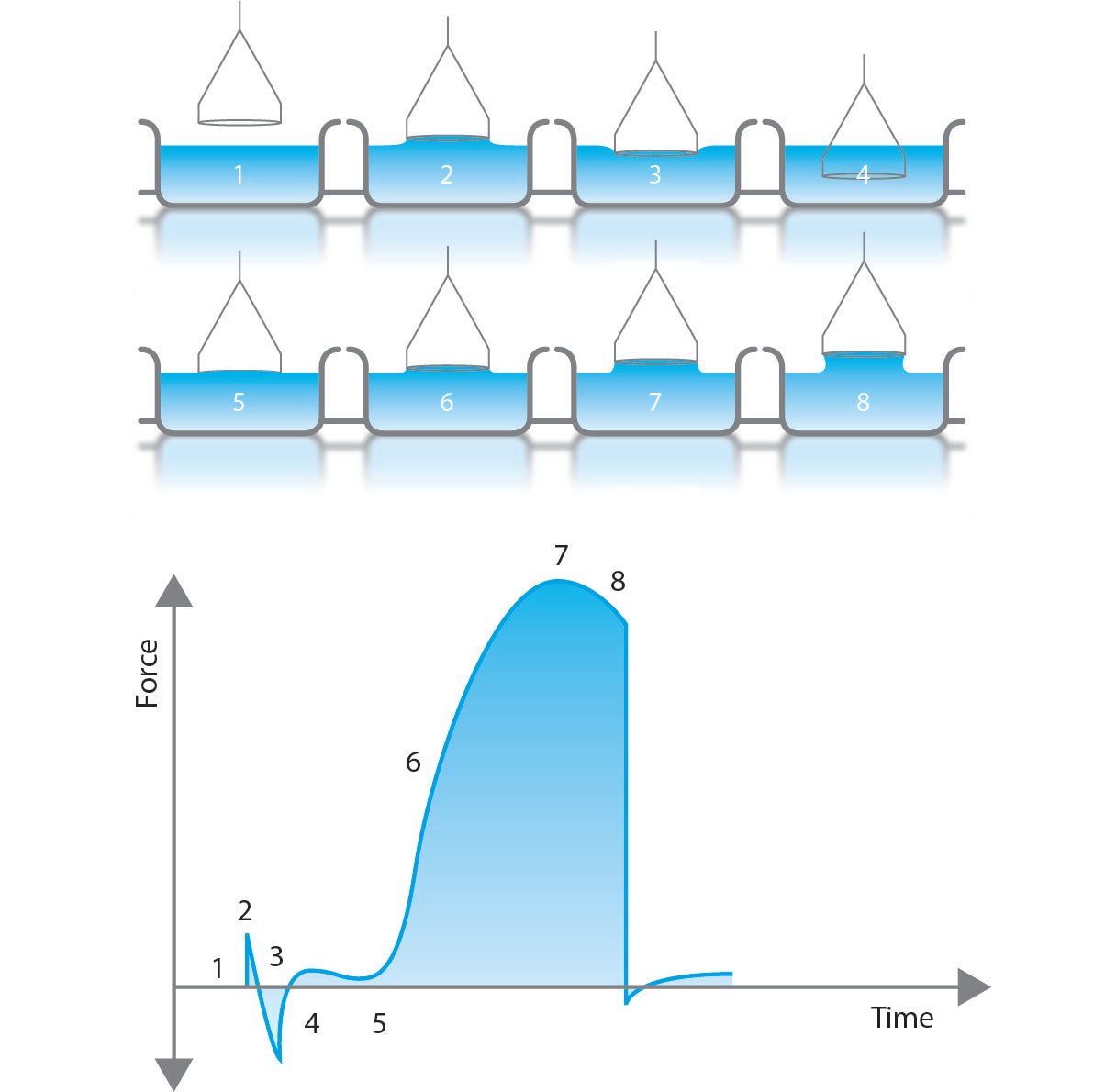

Du Noüy method utilizes the interaction of a platinum ring with the surface of the liquid. The ring is submerged below the interface by moving the stage where the liquid container is placed. After immersion, the stage is gradually lowered, and the ring pulls up the meniscus of the liquid. Eventually this meniscus tears from the ring. Before this event, the volume (and thus the force exerted) of the meniscus passes through the maximum value and begins to drop before the actual tearing event.

Du Noüy method utilizes the interaction of a platinum ring with the surface of the liquid. The ring is submerged below the interface by moving the stage where the liquid container is placed. After immersion, the stage is gradually lowered, and the ring pulls up the meniscus of the liquid. Eventually this meniscus tears from the ring. Before this event, the volume (and thus the force exerted) of the meniscus passes through the maximum value and begins to drop before the actual tearing event.

In the figure above, the different stages of the experiment can be identified.

1. The ring is above the surface and the force is zeroed.

2. The ring hits the surface and there a slight positive force due to the adhesive force between the ring and the surface.

3. The ring must be pushed through the surface (due to surface tension) which causes a small negative force.

4. The ring breaks the surface and a small positive force is measured due to the supporting wires of the ring.

5. When lifted through the surface the measured force starts to increase.

6. The force keeps increasing until

7. The maximum force is reached.

8. After the maximum, there is a small decrease of the force until the lamella breaks (or the ring is pushed back below the surface).

The calculation of the surface or interfacial tension by this technique is based on the measurement of this maximum force. The depth of immersion of the ring and the level to which the ring is raised when it experiences the maximum pull are irrelevant to this technique. The original calculations are based on the ring with the infinite diameter (or wire) and do not consider the excess liquid that is pulled up due to the proximity of one side of the ring to the other. Nowadays correction factors are routinely used [1,2]. For the utilization of the correction factor, the density of the liquid must be known.

[1] C. Huh and S.G. Mason, Colloid & Polymer Sci. 253 (1975) 566-580.

[2] H.H. Zuidema and G.W. Water, Industrial and Engineering Chemistry 13 (1941) 312-313

A wetting agent is a surface-active molecule used to reduce the surface tension of water.

The term surfactant comes from the word surface active agent. At the interface, they align themselves so that the hydrophobic part is in the air and the hydrophilic part is in water. This will cause a decrease in surface or interfacial tensions.

Surface tension plays an important role in Li-ion battery slurry optimization.

Surface tension plays an important role in the electroplating solution.

When measuring contact angles or making surface tension measurements with a pendant drop, selecting the correct tip or needle for your liquid is crucial.

The surface tension of water is about 72 mN/m at room temperature which is one of the highest surface tension for liquid.

Surface tension is a quantitative measure that can be correlated with a solution’s ability to remove dirt.

Surface tension and wettability are important physical properties that play a significant role in the effectiveness of agrochemicals.

Explains three different methods to measure surface tension.