Superhydrophobic surfaces were an instant hit in the scientific community when they were introduced over two decades ago. Since then thousands of publications have documented superhydrophobicity being achieved on various different substrates, from glass to fabrics.

The great potential of superhydrophobic surfaces was apparent early on. Applications ranging from self-cleaning windows to anti-acing surfaces and non-wetting fabrics appear commonly in the literature.However, it can be argued that superhydrophobic surfaces have not really delivered on their promise since not many commercial applications are currently available.

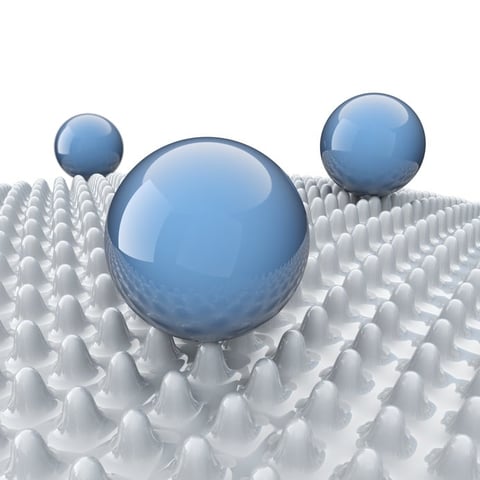

By far the biggest obstacle towards real life applications is the durability of the superhydrophobic surface. If we consider how superhydrophobicity is achieved, the reasons for poor durability are quite obvious. Essentially, superhydrophobicity requires two things:

A primary approach for the fabrication of superhydrophobic surfaces is based on patterning roughness on a solid substrate. As the solid substrate is usually hydrophilic by nature, a hydrophobic coating is then applied to achieve superhydrophobicity. Coatings are however prone to degradation caused by mechanical wear, UV radiation or abrasive particles. Micro- and nanostructures are also affected by the mechanical wear. If the hydrophobic coating is deteriorated or the surface texture is lost, the superhydrophobic properties are diminished.

During the last decade or so, increasing attention has been given also to the durability of the superhydrophobic coatings. It has become evident that no matter how impressive the properties achieved, if these properties are not durable, they are of no use in long term applications. Also the need to be able to compare the durability of different coatings is recognized. This can only be achieved by standardized testing methods for both durability testing as well as evaluation of the wetting properties.

For more information on how the durability of the superhydrophobic surfaces can be evaluated please attend the webinar given by Robin Ras.

Aired: 17, 18 November

Understand how superhydrophobic surfaces are defined, how they work, and how to measure them using contact angle methods. Explore key industrial applications—from self‑cleaning and anti‑icing to drag reduction—and what to consider when evaluating durability.

Single-cell trapping can be done with the help of superhydrophobic and superhydrophilic patterns.

Advancing and receding angles should be measured as the low contact angle hysteresis is also a requirement for superhydrophobicity.

There are three contact angle measurement methods for superhydrophobic surfaces; static, advancing/receding and roll-off angle.

A self-cleaning surface is any surface with the ability to readily remove any dirt or bacteria on it. Self-cleaning surfaces can be divided into three different categories; superhydrophilic, photocatalytic and superhydrophobic.

Blood-repellent surfaces are needed in medical devices that come in contact with blood. The traditional approach has been the use of antithrombotic surface treatments However, these coatings are prone to eventually wear-off. Superhydrophobic surfaces have been proposed as an alternative solution.

With increasing understanding of the superhydrophobicity, the measurement methods to quantify the degree of hydrophobicity deserve some thought.

This video will explain two main methods for measuring dynamic contact angle.