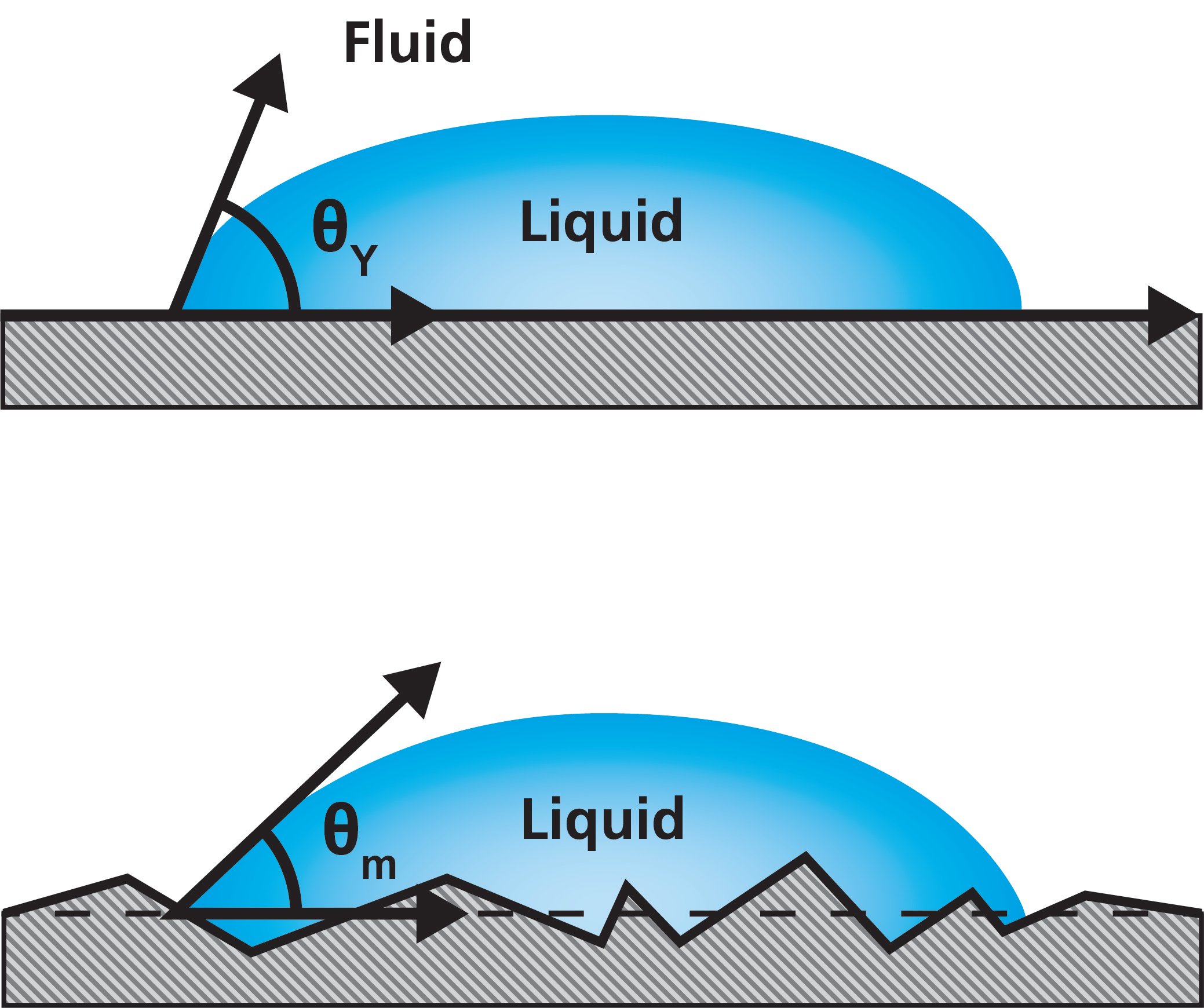

We started the series of different contact angles with a static contact angle. The static contact angle offers a fast way of characterizing the wettability of the solid. The static contact angle can, however, be problematic as there is no one static contact angle for any real surfaces. In a typical experiment, you measure the static contact angle on several different spots on the same sample and calculate the average contact angle over the entire area. In some cases, measuring several spots might not be possible, for example, if the area is too small. And even if several measurements are possible, you can end up having a wide spread of contact angle values. One reason for the contact angle variation is surface roughness.

Roughness corrected contact angle, is an angle where the effect of surface roughness is taken away. As a droplet is placed on the surface, it forms a drop whose shape is dependent on the chemical interactions between the surface and the liquid but also the surface roughness. As you measure contact angles, around the same surface, you often see variation between different measurement points. It is impossible to say though, whether the variation is due to surface chemistry or surface roughness variations over.

The roughness corrected contact angle can be measured by measuring surface roughness on the same spot as the contact angle. The correction is based on the Wenzel equation where the surface roughness factor is used to correlate the measured contact angle to the roughness corrected contact angle.

Using roughness corrected contact angles is most suitable for better estimation of surface free energy. Surface free energies are often calculated to be able to compare the surface free energy of the solid to the surface tension of the coating formulation. As you might remember, for the coating formulation to wet the surface, the surface free energy of the solid needs to be higher than the surface tension of the formulation. If the static contact angle is used for surface free energy calculation, the surface roughness can influence the results significantly on rough surfaces. Using roughness corrected contact angles, will take the effect of roughness away from the results. This way the contact angle values used for the calculations are at least somewhat closer to the equilibrium contact angle.

Although roughness corrected contact angles can bring contact angle values closer to the equilibrium contact angle, it does not take into account the chemical heterogeneity of the surface. Also, to be able to use the Wenzel equation for roughness correction, it’s important to make sure that the droplet is at the Wenzel state when on the surface. This means that the drop needs to wet the cavities and holes and no air should be trapped between the surface features.

If you would like to read more about roughness corrected contact angles and how they can be measured, please download the white paper through the link below.

Learn how to use contact angle measurements to evaluate surface cleanliness on different materials and link cleaning steps to reliable adhesion and coating quality.

Learn how wettability, surface free energy and surface roughness define paper and paperboard surface properties – and how to measure them for reliable print, coating and sealing performance.

Smart materials are materials that sense a change in their environment and respond in a useful, reversible way.

Discover how contact angle measurements help optimize plasma treatment for improved wettability and adhesion in industrial applications.

Discover why contact angle is essential for adhesion, coatings, and quality control. Learn how surface wettability impacts product performance.

Discover why PFAS-free coatings are needed, the challenges they present, and key strategies for developing high-performance alternatives.

At the heart of droplet formation are two key molecular forces: cohesion and adhesion.

Contact angle measurements provide a golden standard for evaluation of surface properties for quality control.

Contact angle is the angle a droplet forms in contact with a solid surface. Thermodynamically, it is a balance between cohesive and adhesive forces.