Wettability is a prerequisite to good adhesion. Because of that, the wettability of the solid is often measured to evaluate the adhesion. In principle, water contact angle measurement can be used as it provides the first approximation of the surface wettability. However, for in-depth analysis more sophisticated solutions are needed. Wetting and adhesion analysis has been added to our all-inclusive OneAttension software and is available for download for all OneAttension customers. In this blog post, the use of the new software module is explained.

How well liquid can wet the solid comes down to the interactions between their polar and dispersive parts. In principle, when the polar and dispersive components of the solid are known, it’s possible to compare the interaction with any liquid with these two properties known. If the dispersive and polar components match, the liquid will wet the solid completely. To be able to perform this analysis, different software tools are needed. First, if the surface free energy of the solid is unknown, it has to be determined through contact angle measurements. Surface tension components of the formulation should also be determined separately. The wetting and adhesion analysis can then be created, and properties of solids and liquids added. The wetting and adhesion analysis provides a visual tool to compare the properties of several solids and liquids with each other.

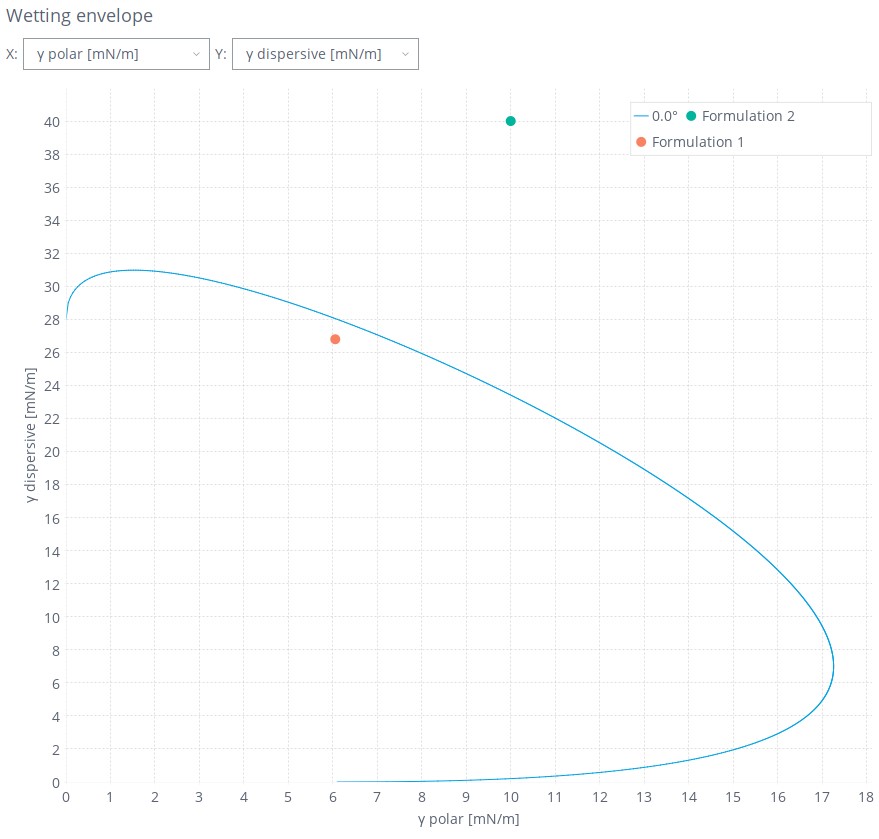

In some applications, the solid surface is predetermined and the properties of the liquid need to be optimized. For example, different paint formulations are tested to find the best one for a given solid. In this case, the solid surface cannot be modified, or can only be modified by cleaning and adding a primer.  To improve the adhesion further, the paint formulation needs to be changed. In the example, two formulations are plotted against a primed drywall. From this simple plot, it can be seen that formulation 1 can wet the primed drywall completely whereas formulation 2 would require some further modifications.

To improve the adhesion further, the paint formulation needs to be changed. In the example, two formulations are plotted against a primed drywall. From this simple plot, it can be seen that formulation 1 can wet the primed drywall completely whereas formulation 2 would require some further modifications.

In other cases, the coating formulation might be set but changes to the solid surface can be done. This is the case often when polymers are coated for various applications as the surface free energy of the polymer is typically very low and adhesion to untreated polymer surface poor.

If you would like to learn more about wettability and adhesion, please sign up for the webinar through the link below.

Learn how to use contact angle measurements to evaluate surface cleanliness on different materials and link cleaning steps to reliable adhesion and coating quality.

Standard contact angle measurement considers the surface's chemical properties. The influence of surface roughness is added by utilizing the Wenzel equation.

Cohesion and adhesion are fundamental concepts in the study of physics and chemistry, playing crucial roles in various natural and industrial processes.

Surface inspection is done to guarantee optimum surface properties for coating and bonding

A spreading coefficient is a measure of the wetting behavior of a liquid on a solid surface.

Depending on the strength of these forces, the adhesion failure can be either adhesive, cohesive, or substrate failure.

One of the main challenges in PCB manufacturing is the adhesion of the conformal coating. Contact angle measurements can be used to predict adhesion.

Adhesion problems are one of the main reasons for the failure of the product. Read to find out how contact angle measurements can help solve the problem.