Bonding and coating are standard processes in the manufacturing of a multitude of products. Bonding is used to attach two materials for improved product performance while coating is applied to protect and finalize the surface of the product. The success is determined by the adhesion of the bond or coating as weak adhesion will, in the worst case, lead to the failure of the product. To ensure good adhesion, the wettability of the surface plays a pivotal role. The wettability of the surface should be inspected before bonding or coating.

To ensure good adhesion, the surface properties need to be optimized prior to bonding or coating. This is typically done by etching or cleaning the surface. The purpose of this is to prepare the surface for subsequent process steps.

In cleaning, the contaminants are removed from the surface. Contaminants are typically hydrophobic, like grease, which would decrease the wettability of the surface. In addition, as the dirt is typically quite loosely bound to the surface, leaving it would lead to weak spots in the coating.

Surface etching, on the other hand, is typically done for polymers to change their inherently hydrophobic surface to hydrophilic. Again this step aims to improve the wettability of the surface.

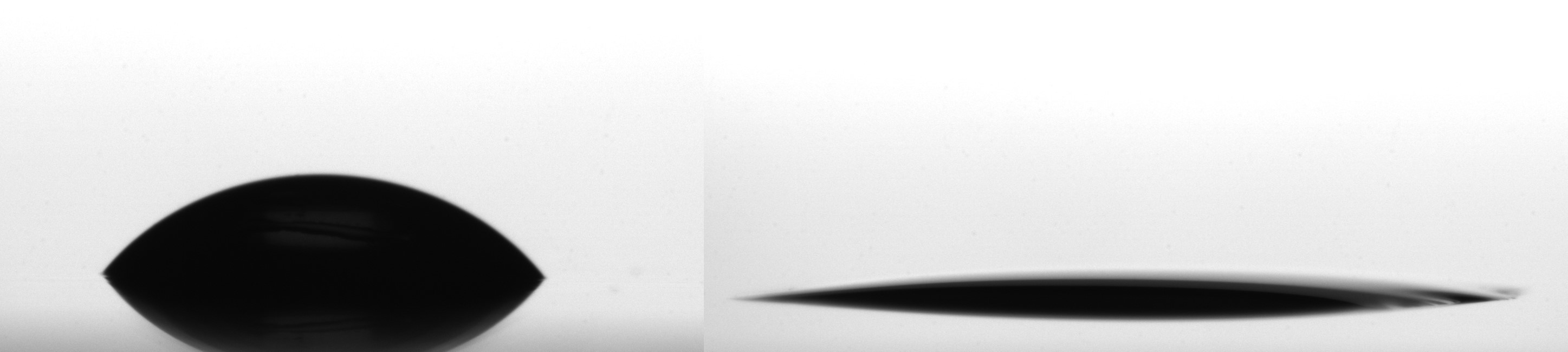

Water contact angle measurement is a fast method the check the quality of the surface. The droplet is placed on the sample surface and the angle is optically measured. Droplets can be created with the manual syringe or with automated dispensers. The entire measurement takes only a minute to conduct and will immediately show whether the surface is ready for the next process step.

If you would like to learn more about contact angle measurements and how they can be used to predict adhesion, please watch the webinar through the link below.

Learn how to use contact angle measurements to evaluate surface cleanliness on different materials and link cleaning steps to reliable adhesion and coating quality.

Standard contact angle measurement considers the surface's chemical properties. The influence of surface roughness is added by utilizing the Wenzel equation.

Cohesion and adhesion are fundamental concepts in the study of physics and chemistry, playing crucial roles in various natural and industrial processes.

A spreading coefficient is a measure of the wetting behavior of a liquid on a solid surface.

Wetting and adhesion analysis has been added to our all-inclusive OneAttension software and is available for download for all OneAttension customers.

Depending on the strength of these forces, the adhesion failure can be either adhesive, cohesive, or substrate failure.

One of the main challenges in PCB manufacturing is the adhesion of the conformal coating. Contact angle measurements can be used to predict adhesion.

Adhesion problems are one of the main reasons for the failure of the product. Read to find out how contact angle measurements can help solve the problem.