A challenge with advanced scientific equipment, such as QCM-D, is that an expert user can be required to generate high quality data. To enable more users to benefit from the QCM-D technology, we developed QSense Omni - QSense 4th generation platform which is designed to lower the knowledge barrier needed to produce high quality QCM-D data.

A challenge with advanced scientific equipment is that expert user skills can be required to generate high quality data, and QCM-D is no exception. QCM-D is a highly sensitive technology measuring surface interaction on a nanoscale with high precision. However, this also makes the technology sensitive to external factors and unwanted variations due to differences in manual handling, cleaning procedures etc. It can require long experience and special expertise to develop reliable and reproducible data. We have noted that spending time with our instruments, and running lots of experiments, the end-user will over time acquire a fundamental understanding of the working principles of the QCM-D technology and develop an intuition for what aspects of the different measurement steps that are critical and have a major impact on the quality of the produced data. Learning how to interpret the, sometimes subtle, signs indicating that something is not quite right, the superuser will develop a special touch which may take many years to master, and which is difficult, if not to say impossible, to transfer to another user. In fact, it is not rare that measurements performed by a novice user, meticulously following the QCM-D best-practice instructions, may turn out very different from those performed by the expert user even though the measurement preparation, setup and performance seemingly was identical in the two cases.

One way to overcome the expert user requirement could be to de-couple as much as possible of the critical measurement setup- and execution steps from the instrument operator, i.e., to make the measurement operator-independent by transferring the critical key procedures, checks, and decisions to the instrument. The instrument is better equipped to identify subtle disturbances, and it can make decisions based on identical criteria every time. Additionally, the instrument user interface could be so intuitive, and guiding the user in such an efficient way, that an expert user would not be needed. Not only will this approach reduce the risk of investing lots of time and resources in one, or a few, QCM-D technology knowledge bearers, but in organizations where one or more dedicated users are still preferred, the start-up training of these individuals will be swift, and more users could easily be added if/when desired without compromising the data quality.

One of the key ambitions with QSense 4th generation QCM-D platform was to lower the knowledge barrier needed to produce high quality QCM-D data. We wanted more users to be able to access and benefit from the information provided by QCM-D without having to invest years and years in training to gain sufficient experience, and without wasting time and resources on measurements with bad setup conditions resulting in low quality data. To realize this ambition, we have taken automation and user independence to the next level. The ease-of-use and automation initiative help and guide the user throughout the whole process, spanning measurement setup, execution, and post-measurement.

Below are listed some of the features that were implemented to address the superuser requirements and reduce the need of an expert user:

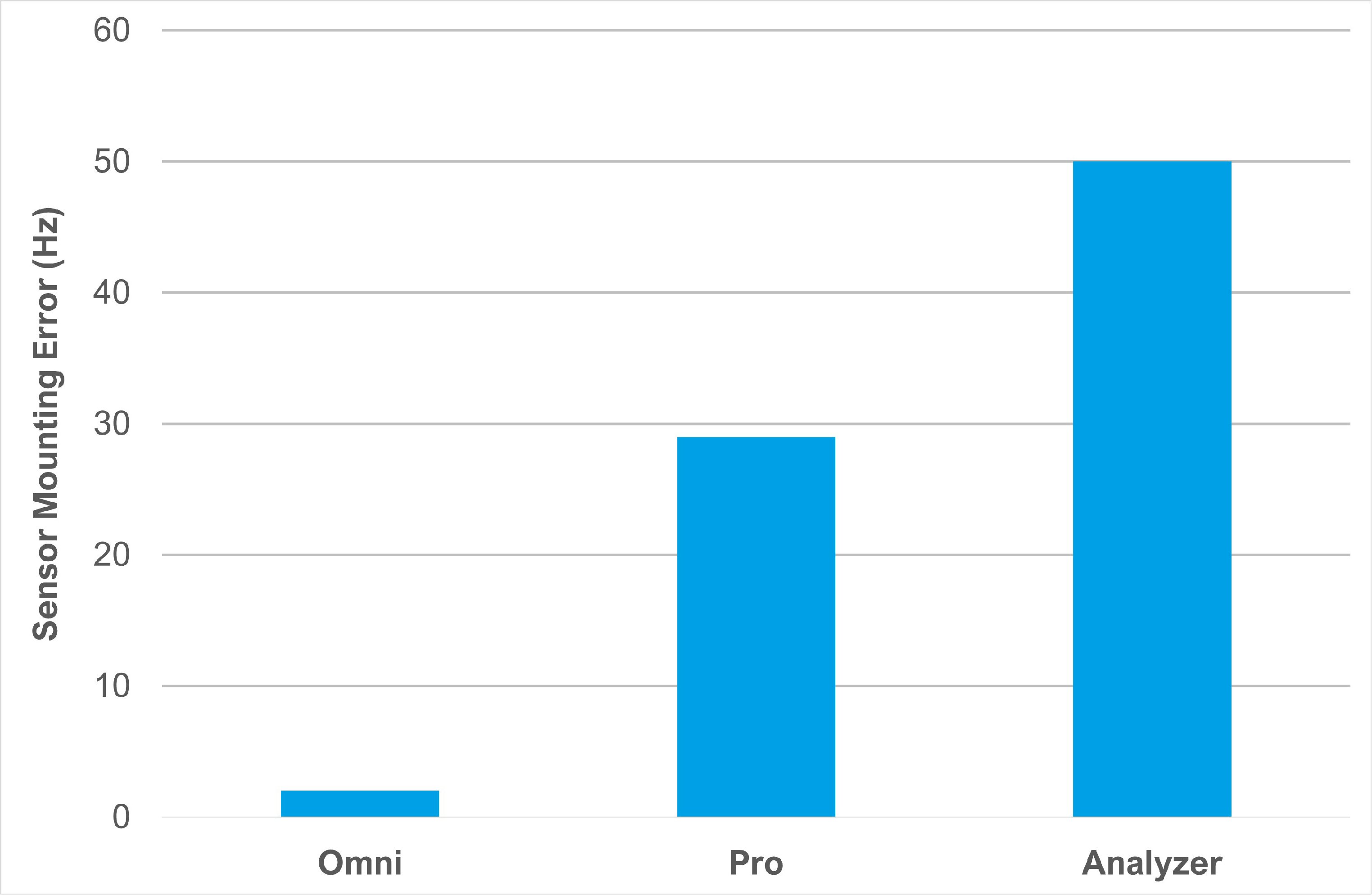

Figure 2. A graph showing the variation in frequency when remounting the sensor in the different QSense instruments, Omni, Pro and Analyzer. Mounting and remounting the sensor multiple times, there is a variation of 50 Hz in the Analyzer. For QSense Pro, the corresponding error is 28 Hz whereas that number is as low as 2 Hz for QSense Omni. This low variation increases the possibilities of measuring coatings applied ex-situ.

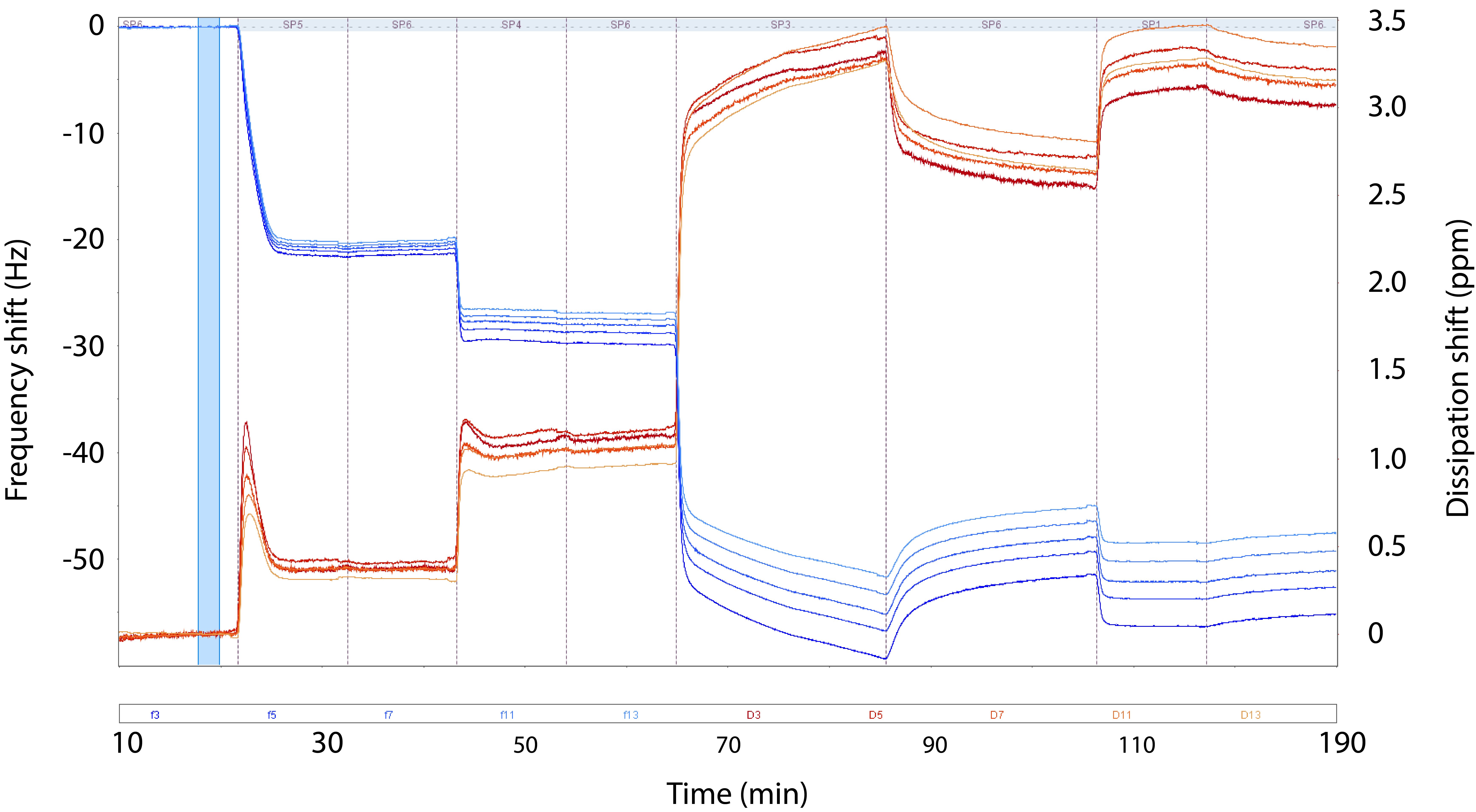

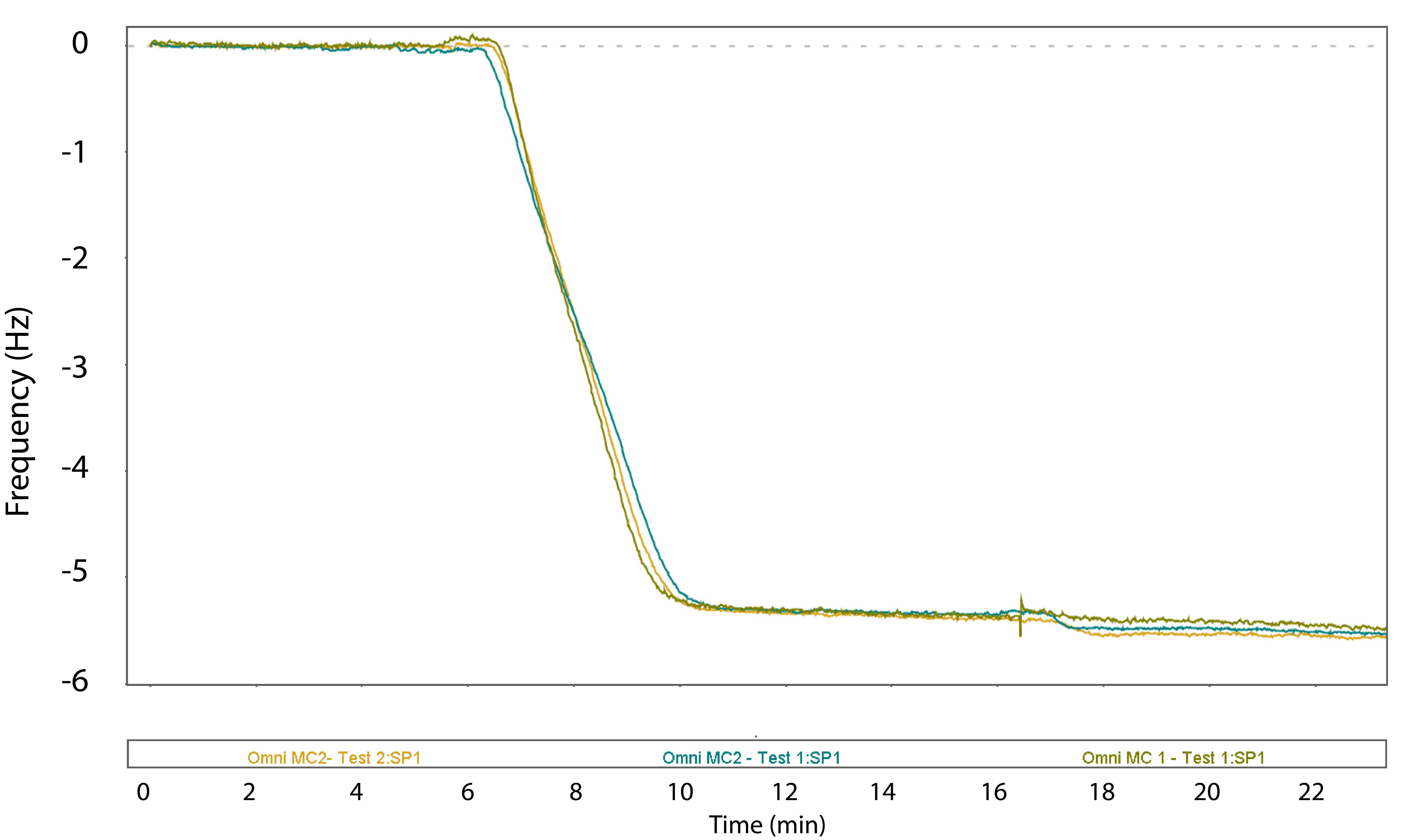

Figure 3. A graph showing a triplicate of frequency changes over time. Each trace showing the adsorption of Poly-L-Lysine (PLL) to silica surface, QSX 303.

QCM-D is an advanced scientific technology that can measure surface interactions with high precision on a nanoscale. However, due to its sensitivity to external factors and variations in, for example, manual handling and cleaning procedures, it can require “super-user skills”, i.e., specialized knowledge and experience to generate reliable and reproducible data. To overcome this challenge and enable more users to benefit from the QCM-D technology, we have developed QSense 4th generation QCM-D platform, a sophisticated instrument designed to minimize the user knowledge required to produce high-quality data.

Download the technical whitepaper to learn more about QSense Omni design and features.

Learn how QSense QCM-D reveals protein–surface interactions and adds interface-focused insight to biopharmaceutical formulation and stability work

Learn how QSense sensors enable application‑relevant biointerface interaction analysis and explore our sensor offering for different areas

Learn how QSense QCM D can be used to analyze swelling of thin films, including magnitude and dynamics.

Read about how molecule-surface interaction processes such as adsorption and desorption can be analyzed with QCM-D.

Learn best practices and step-by-step methods for accurate QCM-D coating thickness measurement on QSense sensors using QSense Omni.

Compared to QCM, QCM-D measures an additional parameter, and provides more information about the system under study.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Discover how QSense QCM-D helps tackle fouling challenges across industries

Discover how QCM-D enables real-time, label-free analysis of supported lipid membrane formation, structure, and dynamics for advanced research

Jennie Ringberg is a former employee at Biolin Scientific. She was the Global Technical Product Manager for QSense and also held roles as Application Specialist for QSense, In-House Sales Manager, and Academy Manager. Jennie holds a Master of Science in Bioengineering from Chalmers University of Technology and spent the first years after graduation focusing on membrane proteins and how to identify and characterize these in the best way.