Imagine a scenario where you have just finished a set of successful QCM experiments, and now it is time to analyze the data. You are mainly interested in the changes of mass and thickness so this is what you plan quantify. Now, you must decide which method to use – will it be the Sauerbrey equation or viscoelastic modeling? So, what are those rules of thumb that tell you when to use which approach? Don’t worry – here you have them - the guidelines on how to assess which method to use.

The Sauerbrey equation is valid for thin and rigid films, where the energy losses are small. If these conditions do not apply, the viscoelastic nature of your film needs to be considered and viscoelastic modeling should be used. So how can you tell if you stand before one situation or the other? The key is to look at the Δf and ΔD data, i. e., changes in recorded frequency and dissipation, respectively. Ideally these should be recorded for multiple harmonics of the QCM.

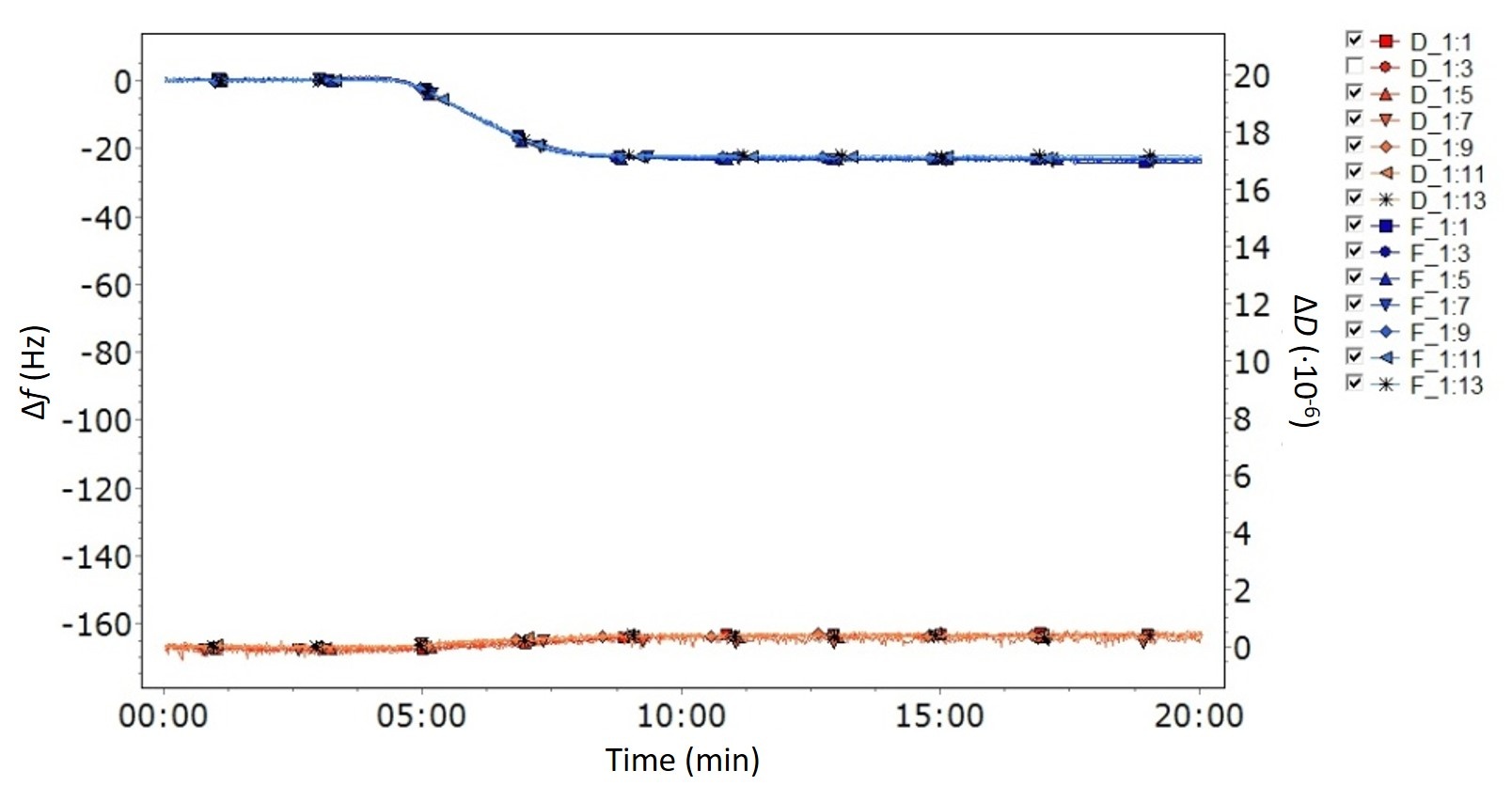

If the change in energy loss is recorded, you can tell that the layer is rigid and that the energy losses are small by the fact that ΔD is close to zero, Fig. 1. Another key characteristic of a rigid layer is that the harmonics are overlapping. A typical scenario would be the one shown in Fig 1, where it looks like only one single harmonic has been recorded.

The Sauerbrey mass is calculated using one of the measured harmonics, and it should not matter which one is used, all harmonics should provide the same answer. If the harmonics overlap, the magnitude of the mass will not depend on which one of the harmonics that is used for the calculation.

Figure 1. A typical situation where the Sauerbrey equation should be used is identified by a low D-value and overlapping harmonics. In this graph, the curves overlap to such an extent that it looks like only one single harmonic is captured.

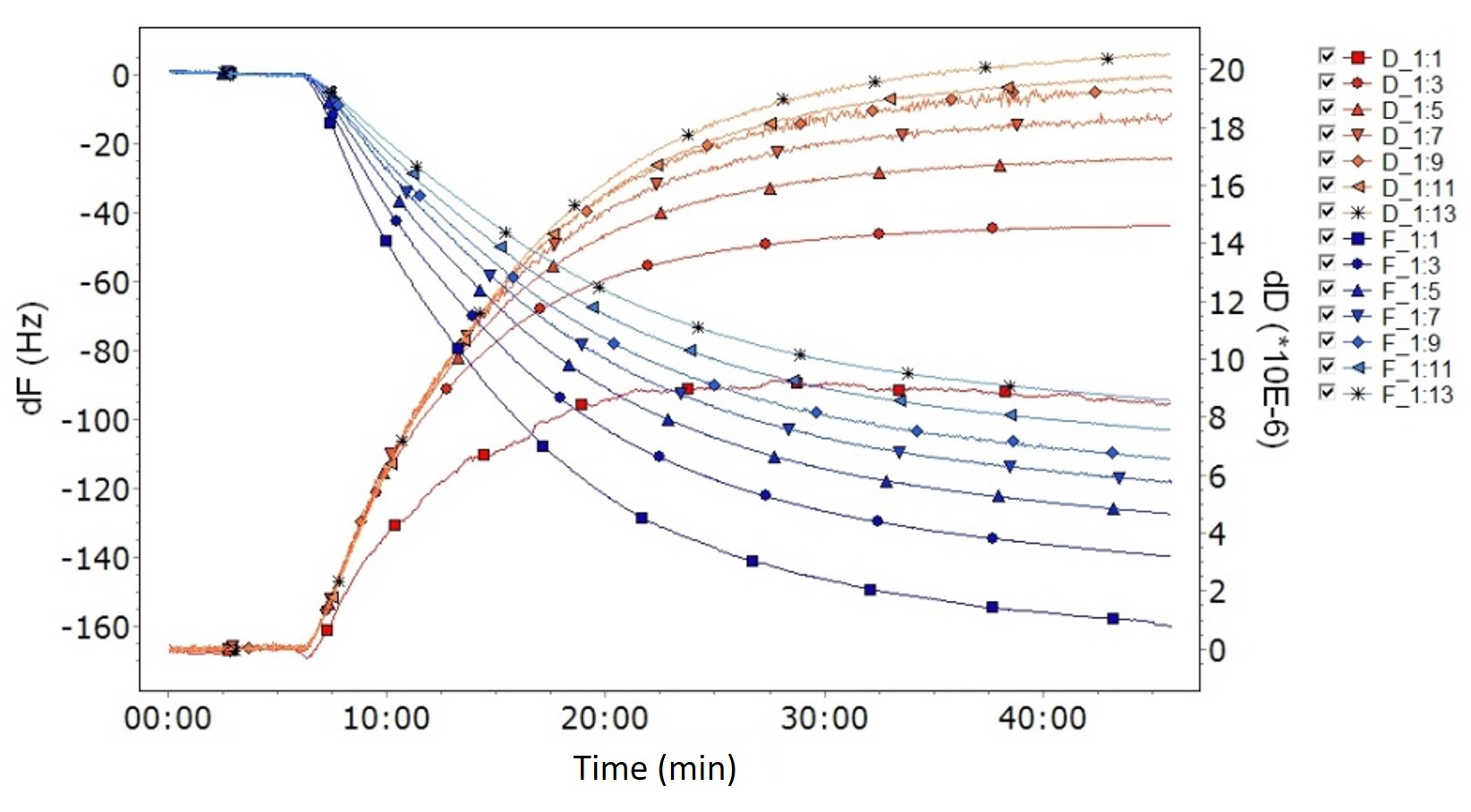

If the layer is thick and/or soft, viscoelastic modeling should be used. A viscoelastic layer is typically identified by two key characteristics in the data, i) the energy losses, ΔD, are larger than zero, and ii) the overtones are spreading. Spreading overtones reveal that the layer properties influence the recorded signals, and each harmonic will provide unique information on these layer properties.

Figure 2. A typical situation where viscoelastic modeling should be used is identified by a large D-value and spreading harmonics, where each curve is clearly separated from the others.

If the layer to be analyzed fulfills the modeling requirements, there are two approaches that could be used to calculate the mass depending on whether the viscoelastic nature of the film needs to be considered or not. Which analysis method to use can generally be assessed by looking at key characteristics in the raw data, f and D, ideally at multiple harmonics.

Download the guide to get a summary of the guidelines on how to assess which analysis method to use.

Editors note: This post was originally published in 2018 and has been updated

Learn how QSense QCM-D reveals protein–surface interactions and adds interface-focused insight to biopharmaceutical formulation and stability work

Learn how QSense sensors enable application‑relevant biointerface interaction analysis and explore our sensor offering for different areas

Learn how QSense QCM D can be used to analyze swelling of thin films, including magnitude and dynamics.

Read about how molecule-surface interaction processes such as adsorption and desorption can be analyzed with QCM-D.

Learn best practices and step-by-step methods for accurate QCM-D coating thickness measurement on QSense sensors using QSense Omni.

Compared to QCM, QCM-D measures an additional parameter, and provides more information about the system under study.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Discover how QSense QCM-D helps tackle fouling challenges across industries

Discover how QCM-D enables real-time, label-free analysis of supported lipid membrane formation, structure, and dynamics for advanced research

Learn how QSense QCM-D analysis can reveal membrane fouling dynamics and optimize cleaning strategies for more efficient water treatment

Learn how QSense QCM-D helps detect and prevent surface-induced instabilities in biologics. Join our webinar for insights and practical examples.

Learn about the top QSense sensors for analyzing biopharmaceutical drug-surface interactions in the context of IV bags.