If you are using QCM-D, you are probably aware that to quantify the data, the deposited layer at the surface should be evenly distributed. But why is this important? Here we describe what the mass sensitivity distribution looks like, and why it looks the way it does.

The QCM sensing principle is based on motion. The sensor surface oscillates back and forth, and if mass couples to this oscillatory motion, it will be sensed. The sensing area, i.e., the area that vibrates is called the active area, and is mainly confined to the overlap of the QCM electrodes.

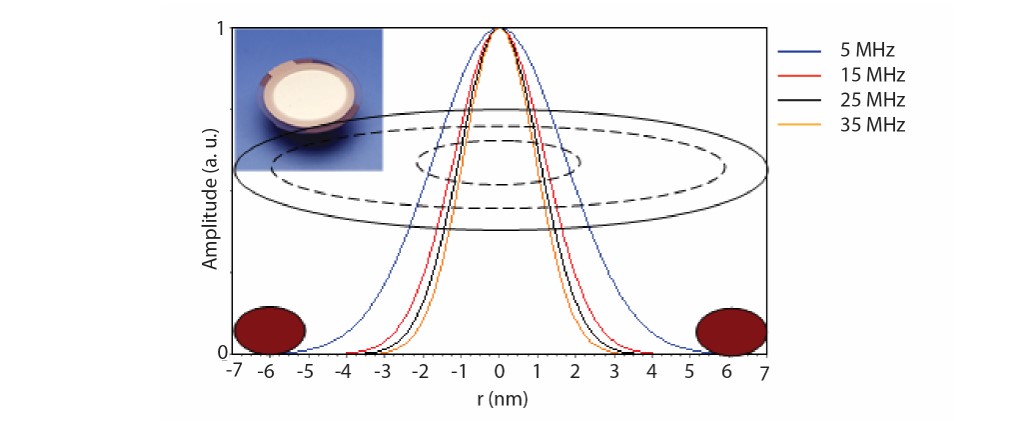

The amplitude of the crystal vibration is, however not constant over the crystal surface but it varies in a fashion determined by geometry of the sensor and the sensor electrodes. In standard QCMs, disk-like sensors and circular electrode are typically used, Fig 1. On such sensors, there is, to a good approximation, a radial dependence of the oscillation amplitude, A(r), according to Eq. 1.

The maximum amplitude, A0, is reached in the middle of the sensor, at r = 0, and then it tapers off towards the sensor edge. The width, c, of this gaussian distribution depends on the harmonic, the higher the harmonic, the sharper the gaussian, Fig 1.

Figure 1. Normalized distribution of the crystal oscillation amplitude of harmonics n = 1, 3, 5 and 7 for a 5 MHz crystal [1]. The width of the gaussian depends on the harmonic, the higher the harmonic the sharper the Gaussian. The large and small dashed circles represent the top and bottom QCM electrodes respectively. The brown ellipses represent cross-sections of the top O-ring.

As already stated, mass that couples to the oscillatory motion of the QCM crystal will be sensed. The force exerted on a particle sitting at the sensor surface is proportional to the oscillation amplitude at that point, and Sauerbrey showed that the differential mass sensitivity, S(r,ϴ), at a distance r from the center of the crystal and at an angle ϴ in the crystal plane, will be proportional to the amplitude. The differential mass sensitivity, which is defined as

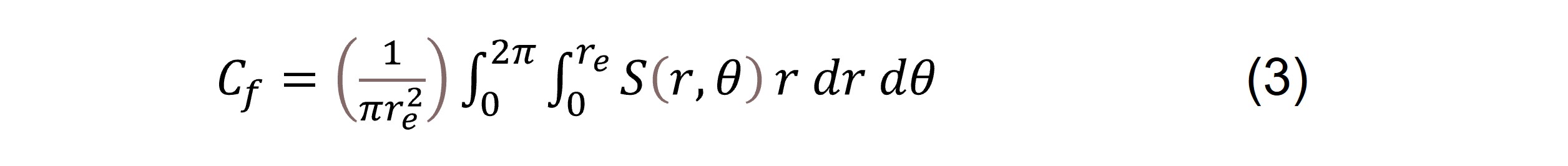

represents the differential frequency change per mass change at a specific location on the sensor surface. Integrating over the entire active area gives the integral sensitivity Cf

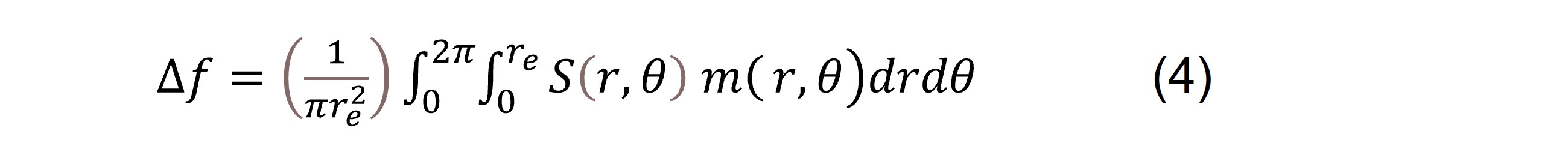

The measured frequency shift, Δf, for mass deposited at the QCM sensor surface will then be

where m(r,ϴ) is the mass distribution.

As discussed above, the frequency shift caused by a localized mass, for example a particle, deposited at the QCM sensor surface depends on the oscillation amplitude at that point. Each localized mass at the surface will contribute to the overall observed frequency shift, and the frequency shift that is recorded, is the sum of all local contributions from the entire sensor surface.

If m(r,ϴ) is uniform, Δf will be linelarly dependent on the layer thickness. In this case, the mass sensitivity, S(r ϴ) is unimportant, and the Sauerbrey equation, eq. 5, which assumes that the added mass is uniformly distributed over the crystal surface, can be used.

If m(r,ϴ) is not uniform, however, the Sauerbrey equation will not generate a correct estimation of the deposited mass.

The QCM mass sensitivity function is related to the oscillation amplitude of the crystal, and this typically has a gaussian distribution. The width of this gaussian depends on the harmonic, the higher the harmonic, the narrower the gaussian. The gaussian shape of the mass sensitivity function means that the frequency response of a localized mass depends on the position where it is placed. The closer to the center, the larger the contribution to the observed frequency shift. The frequency shift that is recorded in a QCM measurement is the sum of all local mass contributions from the entire sensor surface. This is also why a uniformly distributed layer at the sensor surface is important.

Download the overview to learn more about the mass sensitivity function and how an unevenly deposited mass will impact the quantification.

Learn how QSense QCM-D reveals protein–surface interactions and adds interface-focused insight to biopharmaceutical formulation and stability work

Learn how QSense sensors enable application‑relevant biointerface interaction analysis and explore our sensor offering for different areas

Learn how QSense QCM D can be used to analyze swelling of thin films, including magnitude and dynamics.

Read about how molecule-surface interaction processes such as adsorption and desorption can be analyzed with QCM-D.

Learn best practices and step-by-step methods for accurate QCM-D coating thickness measurement on QSense sensors using QSense Omni.

Compared to QCM, QCM-D measures an additional parameter, and provides more information about the system under study.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Discover how QSense QCM-D helps tackle fouling challenges across industries

Discover how QCM-D enables real-time, label-free analysis of supported lipid membrane formation, structure, and dynamics for advanced research