Polyelectrolyte multilayers (PEMs) are created by layer-by-layer deposition – a process where oppositely charged polyelectrolytes are deposited on a solid surface in an alternating fashion. The PEM build-up, and the resulting multilayer, can be analyzed using QSense QCM-D technology. Here we show how.

Quartz crystal microbalance with dissipation monitoring (QCM-D) has been used to analyze polymer-based systems for almost two decades. The method measures two parameters, Δf and ΔD, and provides time-resolved information on mass, thickness, and viscoelastic properties of surface adhering layers. The information provided makes the method suitable to analyze for example the PEM growth process, as well as to characterize the mechanical properties, and structural changes, of the resulting layer.

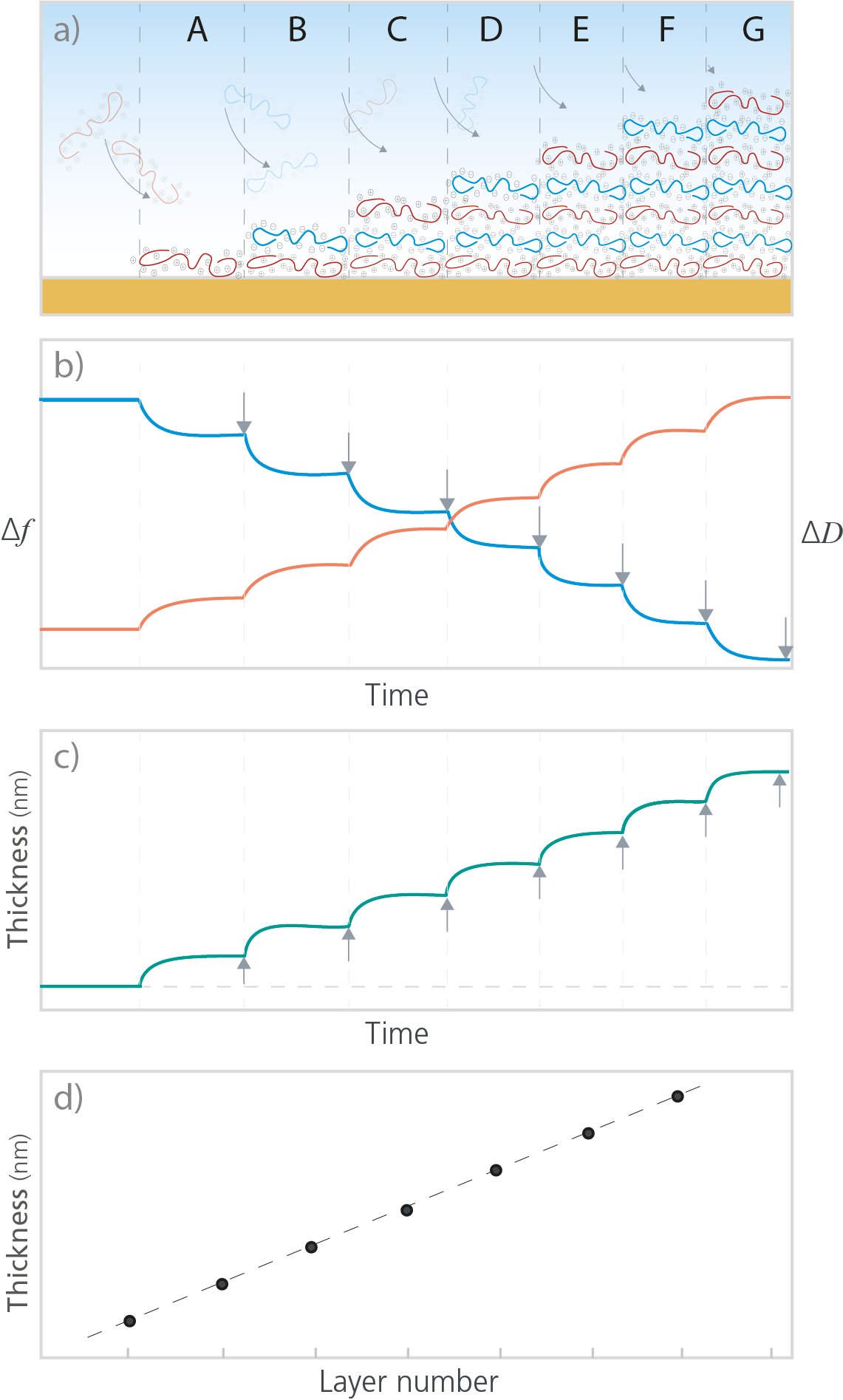

A schematic example of what the build-up, analyzed by QSense QCM-D, could look like is shown in Fig. 1. The PEM growth is reflected by the changes in Δf and ΔD, which can then be used to quantify the layer thickness as well as the mechanical properties of the layer (not shown). The multilayer growth mode, and the thickness increase throughout the build-up process, can then be assessed to reveal whether for example if it is linear or exponential growth.

Figure 1. a) Schematic illustration of a PEM build-up process, where a layer is added in each step A-G. b) The PEM build-up is characterized by QSense QCM-D, where Δf (blue) corresponds to mass changes at the surface and ΔD (red) corresponds to layer softness. As indicated by the grey arrows, the time-resolved data makes it possible to follow the adsorption/binding process, how fast it is, and how much material that is added to the surface. The data shows that for each layer, there is mass added (decrease in Δf) and the layer gets softer/thicker (increase in ΔD). c) The quantified thickness of the PEM as a function of time. d) The thickness plotted as a function of layer number shows that the growth process is linear.

The PEM build-up and layer structure depend on several factors, and running QCM-D analysis at relevant conditions can provide insight into how the growth is influenced by variations in e.g., the polyelectrolyte structure and the external conditions such as pH, temperature, salt concentration.

QSense QCM-D is a surface sensitive technology that is used to monitor PEM-growth as well as the mechanical properties of the resulting layer as a function of measurement conditions. For example, QCM-D can be used to

Download the overview to learn more about QSense analysis of polymer-based systems.

Read about how QSense QCM-D was used in the development of a new thermoresponsive polymer brush with antifouling properties for biomedical applications.

Find out more about how to use QCM-D for polymer characterization and to analyze polymer interactions at surfaces.

Polymer brushes, polyelectrolyte multilayers and hydrogels are typically used to achieve desirable properties. Key parameters influencing these properties are layer conformation and the degree of hydration. Here we show a straightforward way to measure polymer brush swelling and collapse.

The versatility of polyelectrolyte multilayers, PEMs, is high, which makes them interesting for e.g. biomedical applications. The functionality is largely determined by the layer properties, which needs to be understood to be tailored. Here, we show how PEMs can be characterized with QCM-D.

Polymers and polyelectrolytes of various conformations are used in many applications where there is a need to tailor the interfacial properties to promote a certain interaction with the surrounding environment. Here we show how polymer layer crosslinking and collapse can be characterized.

Thanks to the complementary information combinatorial QCM-D and ellipsometry can provide, these two allow one to simultaneously monitor both polymer brush swelling and deswelling behavior, as well as attachment and detachment of protein.

The webinar will illustrate the benefit of using two complementary technologies simultaneously to characterize thin film build-up and behavior.