Chemical mechanical planarization (CMP), relies on several nanoscale surface interaction processes, and so does a successful CMP result. Irrespective of whether your ambition is to develop and customize high performing slurries, to improve contamination control, or to achieve reliable CMP protocols, it all starts with an understanding, and control of, the surface-molecule interactions involved.

QSense® QCM-D technology is used in molecule-surface interaction analysis and optimization of CMP-related processes. The method can, for example, be used to analyze

The chemical part of CMP represents a key aspect of the method. It is therefore important that this is optimized for the end use. Both in the development of new slurries and protocols, as well as in the improvement of existing ones, it is important to understand the chemistry and the surface interactions involved. With QSense technology you can study surface processes related to, for example, slurry additives and their interaction with the surface. Questions that could be answered are for example:

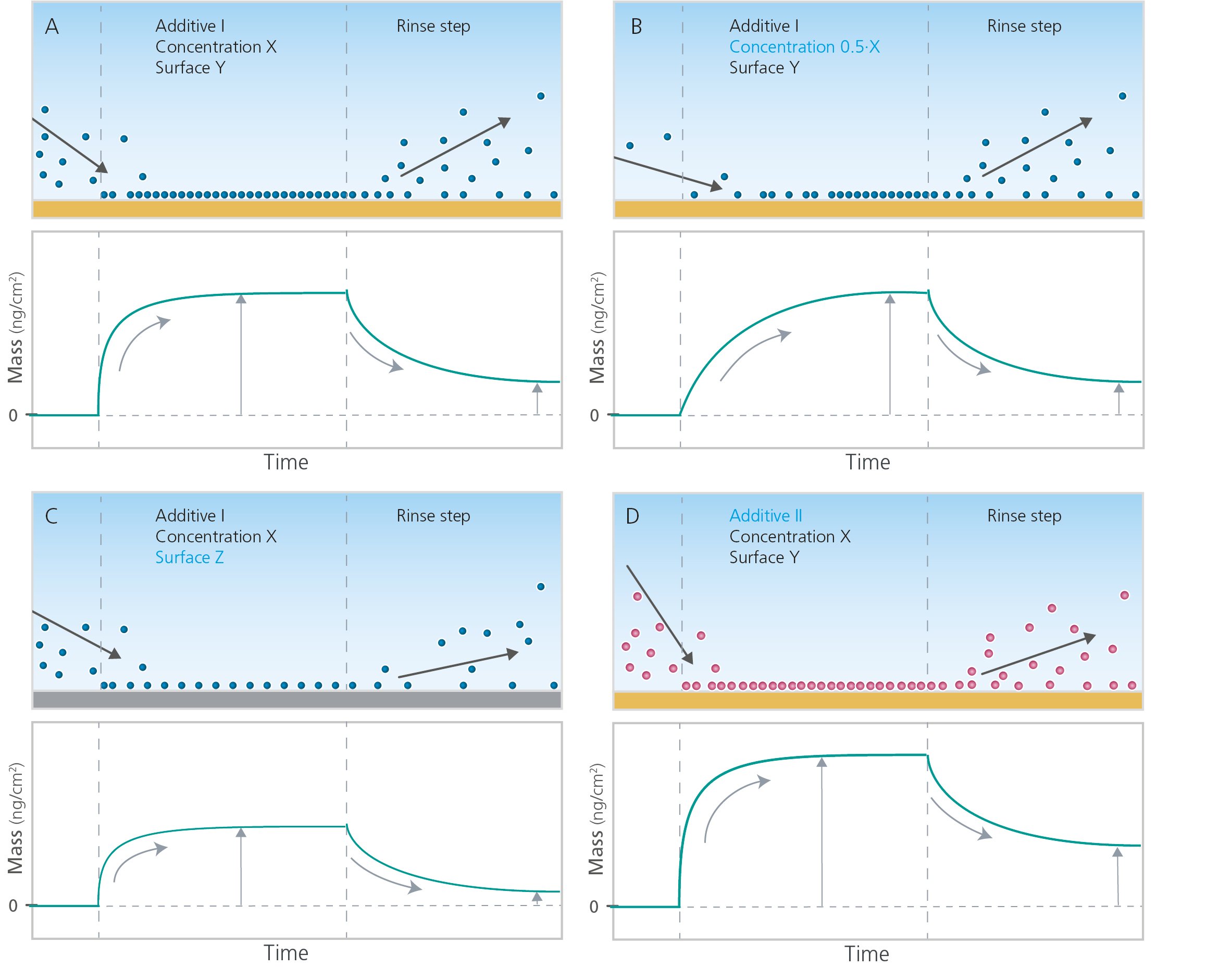

QSense is a surface sensitive technology that gives you a new set of eyes in the study of surface interaction processes. It is based on the Quartz Crystal Microbalance with Dissipation monitoring technology (QCM-D) which allows you to study nanoscale mass, thickness and viscoelastic changes of your surface material or coating. The QCM-D method is time-resolved, which means that you can follow the interaction processes in real-time. Interactions and events that can be analyzed are for example adsorption, desorption, molecular binding, and structural changes such as swelling and crosslinking. For example, you can analyze and compare how additives, additive mixtures, and abrasives interact with the surface of interest, Fig. 1.

Figure 1. Schematic illustration (not to scale) of how the performance and behavior of different additives can be compared using QSense analysis. The example shows four different measurements where the parameter settings, in blue text, are varied relative to the measurement conditions in (A). In (B) the additive concentration is reduced, in (C) the surface material is changed, and in (D) a different additive is used. The time-resolved mass curves reveal the additive - surface interaction rate and the additive net mass uptake in the respective measurement.

Surface interaction processes are highly dependent on the conditions where they take place. Therefore, when working with a real-life system, it is important to mimic these conditions in the experimental set up. As exemplified in Fig. 1, QSense allows you to vary all the key parameters in your process.

Vary for example:

QSense analysis can be used to understand the chemical part of the CMP process. For example, it can be used to

Download the overview to learn more about how QSense analysis can be used in slurry development, customization and optimization

Learn how QSense QCM-D reveals protein–surface interactions and adds interface-focused insight to biopharmaceutical formulation and stability work

Learn how QSense sensors enable application‑relevant biointerface interaction analysis and explore our sensor offering for different areas

Learn how QSense QCM D can be used to analyze swelling of thin films, including magnitude and dynamics.

Read about how molecule-surface interaction processes such as adsorption and desorption can be analyzed with QCM-D.

Learn best practices and step-by-step methods for accurate QCM-D coating thickness measurement on QSense sensors using QSense Omni.

Compared to QCM, QCM-D measures an additional parameter, and provides more information about the system under study.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Discover how QSense QCM-D helps tackle fouling challenges across industries

Discover how QCM-D enables real-time, label-free analysis of supported lipid membrane formation, structure, and dynamics for advanced research