When exploring surface-sensitive technologies for real-time analysis, you’ll often come across the term QCM, which stands for Quartz Crystal Microbalance. QCM is a powerful technique for measuring extremely small mass changes on a sensor surface. But if you’ve browsed the world of QCM instrumentation, you may have noticed another variant: QCM-D. So, what sets QCM-D apart from traditional QCM, and why is it important for your research or application?

Quartz Crystal Microbalance (QCM) is a highly sensitive balance that detects minute mass changes by measuring shifts in the resonance frequency of a quartz crystal sensor. When molecules bind to the sensor surface, the frequency decreases, allowing you to monitor mass uptake in real time.

The “D” in QCM-D stands for Dissipation. Unlike traditional QCM, which only measures mass changes, QCM-D also measures the energy dissipation factor. This additional parameter provides real-time information about the softness or rigidity (also known as the viscoelasticity) of the molecular layers forming on the sensor surface. In other words, QCM-D gives you a more complete picture of what is happening at the surface.

Dissipation refers to the energy lost in the system during each oscillation cycle of the sensor. It is sometimes called the damping of the oscillating sensor. Mathematically, dissipation is defined as 1/Q, where Q is the quality factor of the oscillator. Dissipation can also be described as the energy dissipated per oscillation divided by the total energy stored in the system.

But what does this mean in practice?

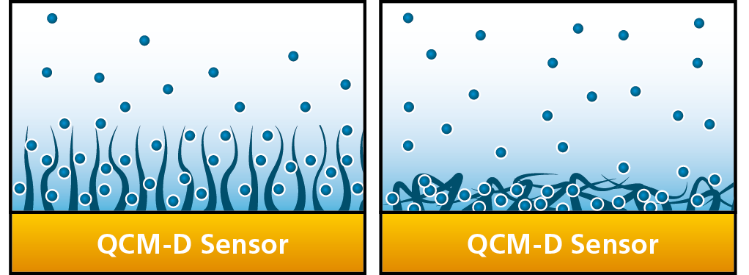

By measuring both frequency (f) and dissipation (D), QCM-D enables real-time characterization of the viscoelastic properties of films, making it possible to monitor conformational changes and molecular arrangements on the surface.

Going into more detail about the first important aspect, the qualitative insight of the time resolved behavior of the system under study, the dissipation parameter will complement the information from the collected resonance frequency. Together the two captured parameters f and D will paint a picture of how molecules arrange themselves on the surface and how the arrangement varies with time; the frequency response of a QCM sensor reflects the amount of mass coupled to the surface, including the mass of solvent which is trapped in the molecular layer. The dissipation reflects the softness of the film.

By tracking both frequency and dissipation over time, you can observe how molecules arrange themselves on the surface and how these arrangements evolve. For example, Fig. 1:

To summarize, QCM-D offers three major advantages over traditional QCM:

By leveraging the dissipation parameter, you can extract more value and insight from your experiments.

Download the white paper to read more about the differences between QCM-D and other QCMs.

Q: What is the main difference between QCM and QCM-D?

A: QCM measures mass changes by monitoring shifts in resonance frequency, while QCM-D measures both mass and energy dissipation, providing additional insights into the viscoelastic properties of films.

Q: When should I use QCM-D?

A: Use QCM-D when analyzing soft or viscoelastic layers, or when you need information about conformational changes, such as layer swelling or collapse.

Q: How do QCM and QCM-D work?

A: Both QCM and QCM-D use a quartz crystal sensor that oscillates at a specific resonance frequency. When molecules bind to the sensor surface, the added mass causes the frequency to decrease. QCM measures these frequency changes to determine mass uptake. QCM-D, in addition to measuring frequency, also monitors energy dissipation, which reveals information about the softness or rigidity (viscoelasticity) of the layer formed on the sensor. This dual measurement provides a more comprehensive understanding of the sample’s properties.

Editor’s note: This post was originally published in November 2017 and has been updated

Learn how QSense QCM-D reveals protein–surface interactions and adds interface-focused insight to biopharmaceutical formulation and stability work

Learn how QSense sensors enable application‑relevant biointerface interaction analysis and explore our sensor offering for different areas

Learn how QSense QCM D can be used to analyze swelling of thin films, including magnitude and dynamics.

Read about how molecule-surface interaction processes such as adsorption and desorption can be analyzed with QCM-D.

Learn best practices and step-by-step methods for accurate QCM-D coating thickness measurement on QSense sensors using QSense Omni.

Discover how QCM-D analysis reveals real-time etching dynamics, helping optimize cleaning processes and protect surfaces from unwanted damage.

Discover how QSense QCM-D helps tackle fouling challenges across industries

Discover how QCM-D enables real-time, label-free analysis of supported lipid membrane formation, structure, and dynamics for advanced research

Fredrik is a Senior Application Scientist at Biolin Scientific. After his Master of Science in Biosensors- and Microsystems technology he has worked with technology and application development in as diverse fields as electroporation, multivariate gas sensing, drug screening and surface science.